I am in the later design stages of a small geothermal cooling loop for an insulated battery cabinet that is located in an outbuilding (shed). After reading through some other threads, I don't find one dedicated to the idea I have in mind, although curiouscarbon gives some pics that illustrate the components of the idea here: https://diysolarforum.com/threads/diy-geothermal.26639/ - please correct me if I just did not find the dedicated thread.

Some givens for my case:

I dug a small, shallow 'well', 1 foot in diameter, about 4 or 5 feet down into the clay ground. The water table is really high, so about 3 feet of this 'well' is underwater (at least right now).

The 'well' is ~3' from the shed, so maybe 4' from the battery cabinet.

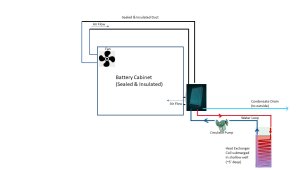

(My thought here is: use an efficient, low-draw pump to circulate water through a small car radiator and into a heat exchange coil inside this shallow 'well'. A fan then pulls air through the radiator and into a 4" duct in the battery cabinet and exhausts out the top (another 4" duct). I'm playing with the details in the late design stage now, and am wondering if others have done something similar. If so, would you be willing to share what has worked/not worked.)

Main purpose:

I intend this loop to keep my NMC batteries cool(ish), esp. during the heat waves we get - up above 40 C (104F) as daytime high for several days in a row.

(The night time temps get down to mid 20's in these cases, but like others, I'm expecting temps to get worse going forward)

At this point, the battery box, with the ducts, is almost finished - insulation is R20 (4" of xps) all around (except for ducts) - I am currently figuring out the doors.

![WP_20220822_15_35_46_Pro[1].jpg WP_20220822_15_35_46_Pro[1].jpg](https://diysolarforum.com/data/attachments/108/108350-6299bbcd86e8e76b282bdf378bbc842b.jpg)

Things I'm wondering about:

-I'm thinking of using a 16' copper lineset for a mini split, just b/c I have it on hand. (The lineset has a 1/4" copper and a 1/2" flexible copper tube). Does using maybe both tubes in parallel make sense, just because I have the material on hand? Or, should I use only 1 dia. If so, would it make more sense to use a longer length than 16' for the heat exchanger?

-what should the total volume be of the water in the closed-loop system?

-anyone have an idea of what to use for the radiator - maybe a small car radiator - I need to integrate it into 4" metal ductwork by fabricating a sheet metal box, I think. . . . but am open to suggestions

-I have just started wondering if it would make sense to make the air duct a sealed loop rather than constantly bringing in fresh air at the bottom left and exhausting at the top right. Any thoughts?

-I have some ideas about a pump, but would appreciate feedback on sources for pumps, but esp. on flow rate specs:

curious carbon suggested https://coldandcolder.com/collections/featured-products/products/12v-micro-water-pump and also https://www.amazon.com/bayite-BYT-7A006-Heater-Circulation-Discharge/dp/B0196WL55G/, which has twice the pumping capacity.

I've also been looking here: https://www.ussolarpumps.com/product-category/circulating-pumps/

The main spec I'm trying to figure out is flow rate. I'm thinking maybe I should get something that allows me to adjust the flow rate so I can trial-and-error it?

In any case, I'll maybe leave it here for now. If you've done anything like this, I'd love to know what worked/what didn't work, etc. I'll post some more pics once I can get a few decent and recent ones, probably in a day or so. Also, please let me know if I've left out relevant details.

Some givens for my case:

I dug a small, shallow 'well', 1 foot in diameter, about 4 or 5 feet down into the clay ground. The water table is really high, so about 3 feet of this 'well' is underwater (at least right now).

The 'well' is ~3' from the shed, so maybe 4' from the battery cabinet.

(My thought here is: use an efficient, low-draw pump to circulate water through a small car radiator and into a heat exchange coil inside this shallow 'well'. A fan then pulls air through the radiator and into a 4" duct in the battery cabinet and exhausts out the top (another 4" duct). I'm playing with the details in the late design stage now, and am wondering if others have done something similar. If so, would you be willing to share what has worked/not worked.)

Main purpose:

I intend this loop to keep my NMC batteries cool(ish), esp. during the heat waves we get - up above 40 C (104F) as daytime high for several days in a row.

(The night time temps get down to mid 20's in these cases, but like others, I'm expecting temps to get worse going forward)

At this point, the battery box, with the ducts, is almost finished - insulation is R20 (4" of xps) all around (except for ducts) - I am currently figuring out the doors.

![WP_20220822_15_35_46_Pro[1].jpg WP_20220822_15_35_46_Pro[1].jpg](https://diysolarforum.com/data/attachments/108/108350-6299bbcd86e8e76b282bdf378bbc842b.jpg)

Things I'm wondering about:

-I'm thinking of using a 16' copper lineset for a mini split, just b/c I have it on hand. (The lineset has a 1/4" copper and a 1/2" flexible copper tube). Does using maybe both tubes in parallel make sense, just because I have the material on hand? Or, should I use only 1 dia. If so, would it make more sense to use a longer length than 16' for the heat exchanger?

-what should the total volume be of the water in the closed-loop system?

-anyone have an idea of what to use for the radiator - maybe a small car radiator - I need to integrate it into 4" metal ductwork by fabricating a sheet metal box, I think. . . . but am open to suggestions

-I have just started wondering if it would make sense to make the air duct a sealed loop rather than constantly bringing in fresh air at the bottom left and exhausting at the top right. Any thoughts?

-I have some ideas about a pump, but would appreciate feedback on sources for pumps, but esp. on flow rate specs:

curious carbon suggested https://coldandcolder.com/collections/featured-products/products/12v-micro-water-pump and also https://www.amazon.com/bayite-BYT-7A006-Heater-Circulation-Discharge/dp/B0196WL55G/, which has twice the pumping capacity.

I've also been looking here: https://www.ussolarpumps.com/product-category/circulating-pumps/

The main spec I'm trying to figure out is flow rate. I'm thinking maybe I should get something that allows me to adjust the flow rate so I can trial-and-error it?

In any case, I'll maybe leave it here for now. If you've done anything like this, I'd love to know what worked/what didn't work, etc. I'll post some more pics once I can get a few decent and recent ones, probably in a day or so. Also, please let me know if I've left out relevant details.