KITROBASKIN

Solar Enthusiast

Admiration for the human ability to discover and manipulate this stuff. What does CT stand for, something transformer?

Interesting question, and like so much with this, not simple to me. ; -)... What does CT stand for, something transformer?

A CT really is a real transformer and works exactly like a real transformer.I suspect north of the Mason Dixon line they're called Current Transformers, but I say call them what you like.

How about probing ChatGPT with similar questions on other topics, to better understand it?

This will expose how broad a vocabulary and sentence structure it offers.

"Can a zip gun fabricated from a car antenna function well enough as a self-defense weapon?"

"Can a respirator fabricated from a coffee filter protect against Covid as well as an N95 mask?"

"Does fruit fly like a banana the way time flies like an arrow?"

"What is the meaning of, 'The vodka was good but the meat was rotten'?"

Also,

"What toroid materials would be best for use in a DIY wrapped current transformer?"

"What toroid properties are best for making a DIY wrapped current transformer?"

| AWG | mΩ/ft | A (60 °C) | A (ΔT0) |

|---|---|---|---|

22 | 16.14 | 3 | 0.9 |

26 | 40.81 | 1.3 | 0.361 |

30 | 103.2 | 0.52 | 0.142 |

There are a few other very important pieces of the jigsaw puzzle including the magnetic length of the core and the magnetic cross section of the core. These extra factors have a very great effect upon the inductance, flux density, and self resonant frequency.Is a $0.40 CT any good? What differentiates a good CT from a bad CT? The only thing that I can see manufacturers could play around with are: core material, wire material, wire gauge, and number of turns.

Not true.I don't think the materials make any difference in the end if you can calibrate around them. That leaves the gauge and windings.

Yes totally correct.First, characteristics of various AWGs:

AWG mΩ/ft A (60 °C) A (ΔT0)

Next, I looked at the ESP32s, the 20 ADCs @ DB11 have a range of 0 to 2500mV with +/- 10mV (slightly more accurate at lower voltages).

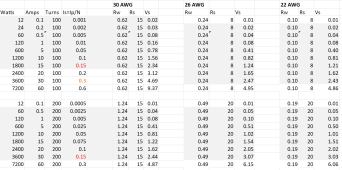

Fired up a spreadsheet to look at the numbers:

The red 0.15 is the maximum safe current for 30 AWG, so 100 turns limits the maximum number of amps that can be measured.

30 AWG - 100 turns 30 AWG - 1000 turns View attachment 134054 View attachment 134055

Maybe ??You can use any value of Rs to adjust the voltage, but I picked one that would give the maximum voltage spread for the maximum current.

Using a 15Ω resistor gives a voltage range of 0 to 2.34, but the accuracy is going to be sketchy at less than 12W.

At 1000 turns and 160Ω, there's no issue with the current even at 60 amps, but the voltage is a little more spread out. So, you could use a 35Ω resistor and get a reading for 0 to 60 amps, but the precision would be less. If you went with a 160Ω resistor and limited it to 15 amps you get the same precision as the 100 turns.

You need to stay within both the current the wire can carry, and the maximum rated output voltage. Below those two limitations you can play around with Rs and output voltage to scale your current measurement. If you need a higher output voltage than that to drive an A/D converter, an amplifier may be required if the CT does not have enough grunt to generate the required output voltage.What about wire gauge? Similar to more turns, it allows higher currents. But the precision range remains the same.

View attachment 134056

Yes, but the big wire with more extra turns all needs to fit onto the core. Bigger core costs more and may quickly become inconveniently large.

Its easy to go big and get much better performance, but nobody wants to spend the cash to do that. All this is usually a commercial enterprise driven by profit. If you are making your own CT, then going big has many advantages, like being much easier to wind and probably more reliable.Maybe, it depends on your requirements. You can go cheap and small and accept the limitations of linearity and accuracy.The math represents the theoretical case, in practice, the values will probably be less.

The IotaWatt is said to be, with calibration, within 1%. So, suspect a 50 amp CT would be good within (60x120x%1) 60 watts.

So, the take-away on this is use the lowest amp CT you can, and if you can calibrate the CT and treat each one differently the cheap ones are probably as good as the more expensive ones (although I'd test the resistant to validate the gauge).

Or you can go larger and have much better overall performance at a higher cost. There is no single correct answer.

The trick as with any engineering is to define your needs and select the appropriate parts.

Doesn't have to be a resistor either, as it's AC it could be an inductor...but AFAIK that's only non-linear with frequency....What this application needs is a good non-linear resistor....