For a little bit of extra protection against accidental contact, I drew up a bus bar cover and a friend of mine created it on his 3D printer. The covers were 12" long and I cut them to fit. He gave me three covers.

Before installation of the covers.

New covers installed.

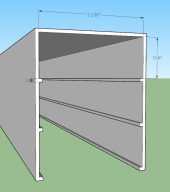

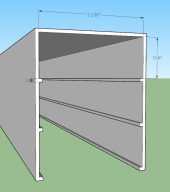

Here's what the covers look like from the end. The covers are designed to snap onto a 3/8"x1" copper bus bar at two different heights, while leaving room for air movement above the bus bar. These aren't the dimensions as it was printed. My friend increased the wall thickness of the cover to give more strength.

I made cutouts in the covers to clear other components. The Dremel worked OK, but I can't seem to cut a straight line.

Because I had them handy, I put plastic cap nuts on top of the studs. It's overkill, I know. But if it keeps me from grounding out something, it will have been worth it.

Before installation of the covers.

New covers installed.

Here's what the covers look like from the end. The covers are designed to snap onto a 3/8"x1" copper bus bar at two different heights, while leaving room for air movement above the bus bar. These aren't the dimensions as it was printed. My friend increased the wall thickness of the cover to give more strength.

I made cutouts in the covers to clear other components. The Dremel worked OK, but I can't seem to cut a straight line.

Because I had them handy, I put plastic cap nuts on top of the studs. It's overkill, I know. But if it keeps me from grounding out something, it will have been worth it.

Last edited: