Is this right? Because as I'm going over this in my head, well, this is getting embarrassing.

Not totally right but also totally not embarrassing.

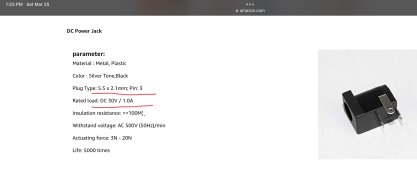

As a connector wears out the resistance will go up which means the current that’s safe to put through it goes down.

Zany has got it exactly right.

Watts matter in general but in terms of melting things we can be very specific and say that really only the HEAT matters in this case.

A perfect example was given:

a similar thing happened to a Chinese RC car charger I bought, the plugs melted at just 12 amps even though it was rated for 30.

So, not even the amps matter, not directly at least. In terms of melting stuff, just the heat matters.

When thinking of heat here we have to break it down more specifically to temperature. Just like Watts=Volts X Amps, total heat/thermal energy can be broken down into components, temperature being one of them. A small mass at a high temp has same energy as larger mass at lower temp, etc.

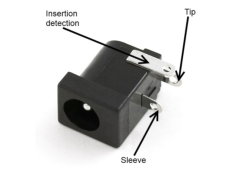

So connectors are rated for a certain amount of amps with the expectation that the connector itself will be a miniscule proportion of the total resistance of the circuit. This is important because voltage in the circuit drops in proportion to resistance. If something is half the resistance of the circuit, it drops half the volts. When voltage 'drops', where does it go? It is converted into some other form of energy such as light, heat, sound, movement, etc..

In the case of wiring and connections, they convert the energy to heat. It is easy to quantify that in terms of Watts of heat because Volts x Amps = Watts.

So let's say a connector has 1 ohm of resistance in a simple series circuit with a total of 10 ohms. That connector will drop 1/10th or 10% of the voltage of that circuit. Let's say it's a 10v circuit. 10v / 10ohm = 1amp. 10v X 1amp = 10 watt circuit. 1 amp flows through this connector. Connector drops 1v, so 1v X 1a = 1watt of heat energy dissipated by this connector.

Now, let's make this connector shitty and raise its resistance. Let's say its 5ohms now. Rest of circuit remains the same which means total circuit resistance is now up to 14ohms. Circuit probably even still 'works'. 10v / 14ohms = 0.7amps. So it's flowing LESS current through the connector now! But it might melt.. how? Well, now it is 35% of the resistance of the circuit instead of 10%, so it's dropping 35% of the volts. 3.5v X 0.7a = 2.45W. It is dissipating more than double the heat, even though it has LESS current going through it.

Even then, Watts are not degrees of temperature. How disperse is the heat that is being generated? If you concentrate all the heat generation in a tiny area, that tiny area will go to a very high temperature. If you spread the heat generation out over a wide area, the actual temp rise will be smaller. It also may or may not be able to dissipate the heat to the surrounding material fast enough to stay under the 'melting temp'. This is the same reason that a certain wire may have a different current rating if it's 'direct burial' in dirt vs in a conduit with other conductors, because it affects how well the wire can get rid of the heat it is generating. The direct burial is using 100% of its surface area as a heat exchanger to a cooler surface and unloading that heat into a truly massive number of lbs of earth. The conduit one has to put heat into air, or into other stupid hot wires it is touching, which means it effectively has a lower limit in its local conditions.

This is an example of how JUST an amp rating is sort of an oversimplification because you can't know how much heat is actually going to be converted in the connector unless you also know the voltage drop across the connector AND how well the connector can get rid of the heat. You can take a perfect 10a connector and make it safely flow 20a by keeping it cold, or you can take a 10a connector and put a bunch of minor mechanical damage on the contact points and it will melt while flowing 4 amps. Or you can put it under a heat lamp and have it melt at 7amps, etc etc. A 10a connector can easily be melted by less than 10amps, due to poor connection issues. When the connector is tiny and half of its contact points are basically impossible to observe because they're buried in the middle of it, you can't blame a person for not noticing it was going downhill before it melts. It's not like you walk into the room and go "WHY IS IT SO HOT IN HERE?!". It probably took less than 10w (focused into a tiny area on a tiny plug) to melt that thing. That sucks, but you don't suck for failing to prevent it. I didn't know all this back when and then, i do now, maybe now you do too, tomorrow it's somebody else. It's certainly nothing to be embarrassed by. Noone was born knowing it!