svetz

Works in theory! Practice? That's something else

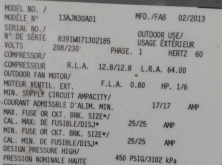

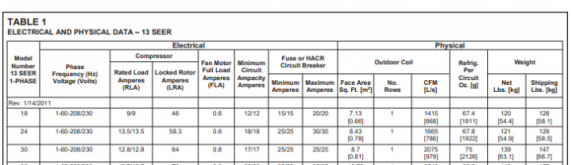

Found the electrical heater element label (under the box where the elements go), RXBH1724C07J, a 5.4 / 7.2 kW heater which from the table should have a maximum OCP of 45 amps. Really impressive how close you were with the handwavium @Supervstech !

So, 25 amps for the condenser and 45 for the air-handler... guess it should have been double-tapped at 70 amps... what were they thinking! ?

So... how to pick compatible circuit breakers.... amazing how many vendors have e82615.

No label on the load center I could see. Pulled a breaker so I could see the "side" label...the model for style e82615 is a Murray MP120. Interestingly it says in big letters "Use only in listed Enclosures Siemens Industry, Inc.". So, must have been from after Siemens bought them.

So two AFCI & GFCI breakers to replace the two kitchen breakers (bathrooms already have GFCI).

25 amp for the condenser

45 amp for the air handler

I also need a handful of GFCI outlets...anyone know a solid brand name?

So, 25 amps for the condenser and 45 for the air-handler... guess it should have been double-tapped at 70 amps... what were they thinking! ?

So... how to pick compatible circuit breakers.... amazing how many vendors have e82615.

No label on the load center I could see. Pulled a breaker so I could see the "side" label...the model for style e82615 is a Murray MP120. Interestingly it says in big letters "Use only in listed Enclosures Siemens Industry, Inc.". So, must have been from after Siemens bought them.

So two AFCI & GFCI breakers to replace the two kitchen breakers (bathrooms already have GFCI).

25 amp for the condenser

45 amp for the air handler

I also need a handful of GFCI outlets...anyone know a solid brand name?

Last edited: