First a little background on my system. I have a ground based array with 32 Adani 365 watt bifacial panels. Each has its own Enphase IQ7-plus micro inverter. I live in Vermont where in the fall and winter has very few sunny days. During a sunny day, the panels will easily max out the inverters, but during the cloudy days not even close.

My thought was to remove half of the inverters and setup the two panels in parallel to drive each inverter. Install a second ground mount array just like the first to use the removed inverters.

By doing this I will:

Does anyone know how to get the 15 minute data from Enphase? It would be very easy to calculate the additional energy collected over a year.

So is this a crazy idea? Thanks - Mark

My thought was to remove half of the inverters and setup the two panels in parallel to drive each inverter. Install a second ground mount array just like the first to use the removed inverters.

By doing this I will:

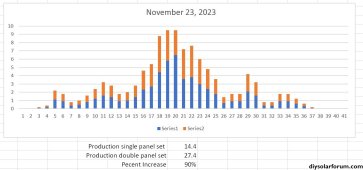

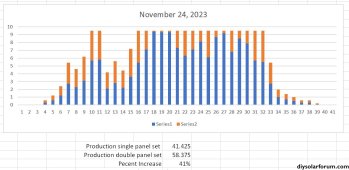

- Basically double my output of the array anytime the inverters aren't maxed out

- Since I won't be increasing the max output, no new permitting

- Won't have to upgrade my circuit panel or provide alternate attachment to the grid

- Can use the existing wire runs from the array(s) to the circuit panel

Does anyone know how to get the 15 minute data from Enphase? It would be very easy to calculate the additional energy collected over a year.

So is this a crazy idea? Thanks - Mark