They are pretty good if you start searching for generic terms. If I want something round, I search for tubing, bushings, rod, drilled rod, spacers etc.

I'll have to improve my McMaster-fu; thanks.

As far as MRBF safety vs a short wire run. If you properly protect the unfused wire length, the risk is minimal. AYBC specs something like 18 inches unfused from the battery pack, but longer is necessary sometimes, just take all possible precautions to prevent shorts. For example most autos have no fusing between the battery and starter motor. Of course they use considerable wire protection and securing mechanisms.

Yeah, like usual, it's a tradeoff. (ABYC actually specifies

7 inches, btw.)

I have long runs, through multiple cabins and areas, between battery packs and the bus up point where they are all joined together. I'm not confident I have perfect wires, crimps, and for that matter clearance over time, in motion, for all of these wires. I also have children and pets living and sleeping above this system every day, and fire is our #1 risk.

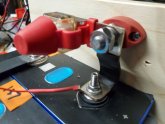

On top of that, at the bus up point I have two 4/0 takeoffs, each also with a 300A MRBF fuse. I was concerned that those master fuses are also only rated to break 2kA current in a 48V design, and so each paralleled pack is separately fused at 100A in kind of a belt-and-suspenders approach. I figure in a catastrophic short that, even if the main fuses fail short themselves, probably the distributed current across the (now 9) packs is below 2000A and enough to start blowing all the small fuses in kind of a cascading way.

Really, I should be using a class T fuse in this application, but in the current design I don't have the space for one. I'm working on a bus bar redesign that might leave room for one, one day. But I'll still be keeping the MRBFs on the actual lithium strings with that change.

Personally I wouldn't put a fuse directly on a cell in a high current application. The temperature risk in the cell could be 10-15F above the rest of the pack under continuous loads. Which might produce issues with balance.

We had this debate in a thread recently, and I completely agree. At the same time as I don't advocate for running small bus bars to their table rating for heating reasons, here I am with the hottest part of my system (the fuse itself) sitting right near a cell terminal!

But, I had to make a trade, and the good news is that I'm rarely sourcing more than 30A through any one of these.

So far, cross fingers, I can't see any degradation on the seven cells that have fuses directly on them after 3 years. I've actually had one cell start to act up, but it was buried back in a string far away from the warmest point.