live4soccer7

Solar Enthusiast

- Joined

- Jun 15, 2020

- Messages

- 670

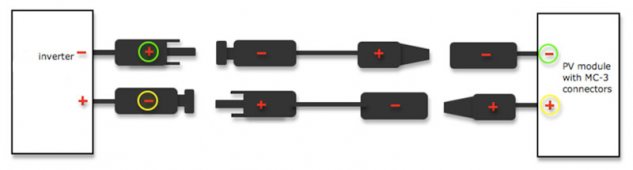

I'm on to terminating today. Why is it that the solar panels have the opposing connector? For example, I have MC4 connectors and it has a + inscribed on it for the male side, but it actually mates up to the negative side of the panel?

It just seems confusing because you're connecting to the negative side of the panel with a connector that has a + PLUS inscribed on it. You would think the panel would have the opposite connector on it and labeled appropriately with a negative so that the connector you're connecting to it with actually matches the polarity with regards to marking.

If any of that made sense. It's always possible I'm missing something, but I don't think.

It just seems confusing because you're connecting to the negative side of the panel with a connector that has a + PLUS inscribed on it. You would think the panel would have the opposite connector on it and labeled appropriately with a negative so that the connector you're connecting to it with actually matches the polarity with regards to marking.

If any of that made sense. It's always possible I'm missing something, but I don't think.