Hedges

I See Electromagnetic Fields!

- Joined

- Mar 28, 2020

- Messages

- 20,784

35mm^2 (or 2 awg) single wire in free air, 256A, you come up with 513 degree C rise?

Please check again. If I look up 190A gives 90C, 60C rise, then at 380A I would expect 4x, 240C rise, 270C temperature.

I'm not sure to what extent a 9" jumper dumps heat into batteries it is bolted to.

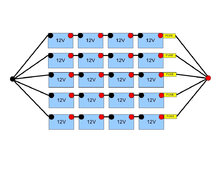

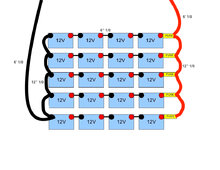

I am inclined to cross connect all batteries, with the idea current will always be shared by two parallel wires that way.

If one cell goes bad, the other two in the 6V battery will cook and outgas. Bye by AGM!

Please check again. If I look up 190A gives 90C, 60C rise, then at 380A I would expect 4x, 240C rise, 270C temperature.

I'm not sure to what extent a 9" jumper dumps heat into batteries it is bolted to.

I am inclined to cross connect all batteries, with the idea current will always be shared by two parallel wires that way.

If one cell goes bad, the other two in the 6V battery will cook and outgas. Bye by AGM!