You need to think of this as several different circuits:

1) Circuit connecting the solar panels and the charger.

2) Circuit connecting the Batteries, Charger and Inverter

3) Circuit(s) connecting the inverter to the cabins.

Each of these will be operating at different voltages and currents, so the wire and fuse sizing must be calculated separately for each circuit.

The circuit that jumped out at me from your description is the 300' @ 20A, 120V.

I assume that is 20amp max per cabin...???

That is a pretty long run for 120V and you could get some hefty voltage drops. In normal house wiring the distances are short enough and current low enough that we just don't worry about voltage drop, but in this case it is worth running some numbers.

EDIT for clarity: You have to consider the round trip distance on the wires so for the 300 ft distance to the cabin I used 600 ft round trip.

In normal house wiring, we would use 14 gauge wire for 20 amps. 14 gauge wire has ~2.5 ohms/1000ft so your round trip of 600 ft would be ~1.5ohms.

Voltage drop = 1.5 ohms * 20 amps = 30 volts drop. That means you would only see 90 volts at the cabin if you start with 120 volts at the inverter.

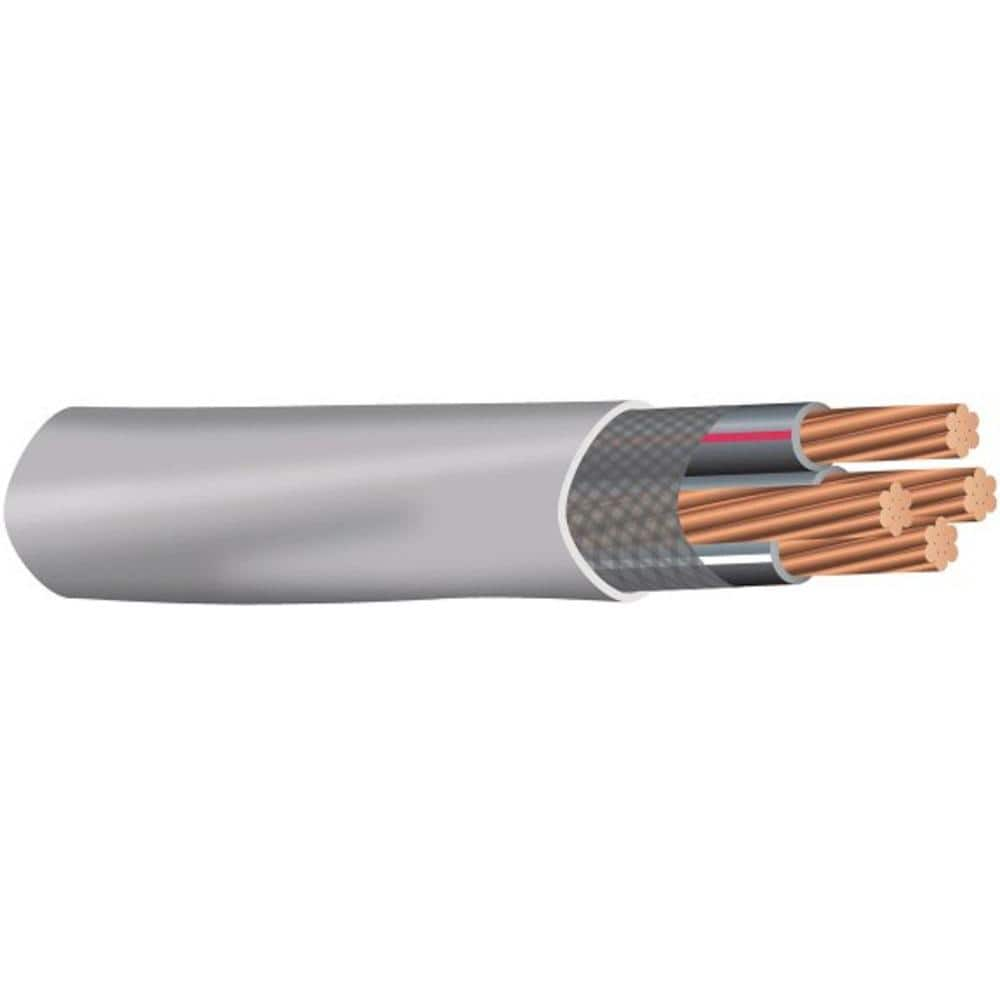

Clearly, that is not acceptable. One solution is to use bigger wire. Lets try 8 gauge.

.6282 ohms/1000ft

.377 ohms/600ft

V=.377*20=7.538 Volts drop. (112.5V at the cabin) From a voltage point of view, this would probably work. However, even with this large wire size you are looking at

150W of line loss! Heavier gauge wires would reduce this loss but would also get pretty expensive.

With the kind of distances you are talking about, you may want to look into a 240V distribution of the AC and put a step-down transformer at each cabin. With 240 volt, you would be running 10 amp and your line loss would be cut to 38W if you stayed with 8 gauge, but you will have some amount of loss in the transformer.

Note: I have not tried to do something like a 240V distribution with step-down transformers. Consequently it is getting out of my ability to give much practical advice on implementation. I am a big proponent of DIY, but this is getting into the world of a micro-grid and you may want to get some professional engineering involved in the system design.

Alternatively, can you have separate systems for each cabin and eliminate the long runs from the inverter?

Note: I used this table for looking up the wire resistance:

https://fiskalloy.com/products/conductor-facts/american-wire-gauge/