callsign4223

New Member

- Joined

- Jul 19, 2020

- Messages

- 10

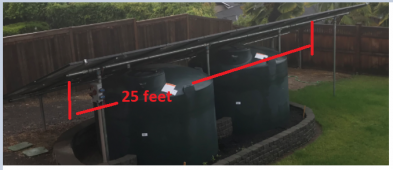

I'm attempting to setup an array as a back porch "cover". Basically, I'm looking at it as a ground mount 10ft in the air. The issue I'm running into is the porch is 25ft across. I was going to use the Iron Ridge ground mount system. It doesn't look like sched 40 pipe is strong enough to span this distance. I'm wondering is maybe steel tubing would be a better option and also wondering if steel tubing would work in the Iron Ridge system.

The one thing I REALLY don't want to do is have to put a support down in the middle of my porch. If that's the only solution this is likely a non-starter with the wife.

The one thing I REALLY don't want to do is have to put a support down in the middle of my porch. If that's the only solution this is likely a non-starter with the wife.