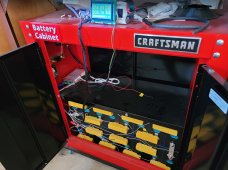

I was thinking about building a ~60KWh battery bank and need a cabinet that is at most 18" deep to fit in the interior side wall of my garage. Using 4 banks of 16 x 280AH LiFePO4 cells the pack would be roughly 200lbs per shelf and 800lbs total. The only reasonably priced thing that I have found that would hold that much weight is this:

Global Industrial Storage Cabinet Ventilated

or

Global Industrial Storage Cabinet Closed

The shelves hold 300lbs each and it is available in ventilated doors and closed doors. I am thinking the ventilated doors would be better to allow the heat to dissipate. Does anyone have any other suggestions for me to look at? Am I going about this wrong?

Global Industrial Storage Cabinet Ventilated

or

Global Industrial Storage Cabinet Closed

The shelves hold 300lbs each and it is available in ventilated doors and closed doors. I am thinking the ventilated doors would be better to allow the heat to dissipate. Does anyone have any other suggestions for me to look at? Am I going about this wrong?