Soiboughtavan

New Member

- Joined

- Jul 12, 2021

- Messages

- 24

Hello!

My name's Luke and my wife and I just bought ourselves a sprinter. Took the leap! I'm undertaking the electrical myself for this project, in hopes to have a better understanding of everything in the case of things going wrong while we're living in the tin can. Yup, we'll be full-time in it for as long as we can make it happen! I've been asking some electrician friends of mine for their opinion on this but they're not all that well-versed in off-grid systems. In advance, I can't begin to explain how grateful I am for communities like this one. Any advice is beyond appreciated. Let's get into it!

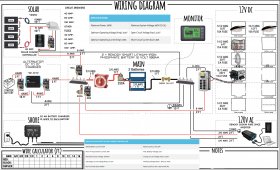

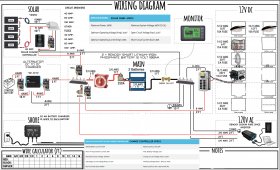

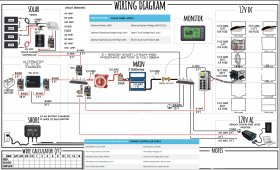

I took the Schematic from Faroutride.com and edited things to give me a better visual of the system I plan on building.

*Note* I'll likely use inline fuses instead of circuit breakers when I build. I'll also be adding a 12V usb dock.

I do already have some questions,

Should shore power connect to the bus bar as well?

Do I need a seperate spot on the bus bar for each connection?

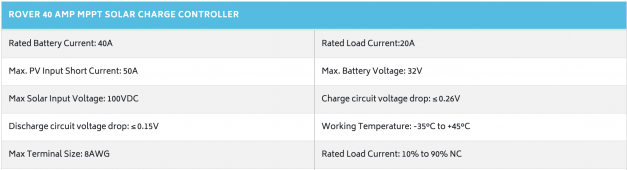

How do I size the wire from the starter battery to the charger?

Will the NOCO Genius 10x2 give me sufficient enough shore power?

I'm considering installing a 2.5 US Gal Bosch Water Heater (Wattage - 1440) as well. Will I have enough storage with solar and the alternator?

Thanks for helping this GREENIE out! I'm thrilled to be a part of this community moving forward. Building this on my own is definitely unleashing the solar geek in me.

Attachments

Last edited: