We used a ground mount from :

snapnrack.com

snapnrack.com

The piers were deep. Ours has to survive hurricanes.

We don't get the full hurricane wind inland, probably 120mph gusts here, max.

I tried to rent an auger, none available, no rental places could tell me how long.

As we have lots of fence posts to replace, I just bought an auger and the related bits.

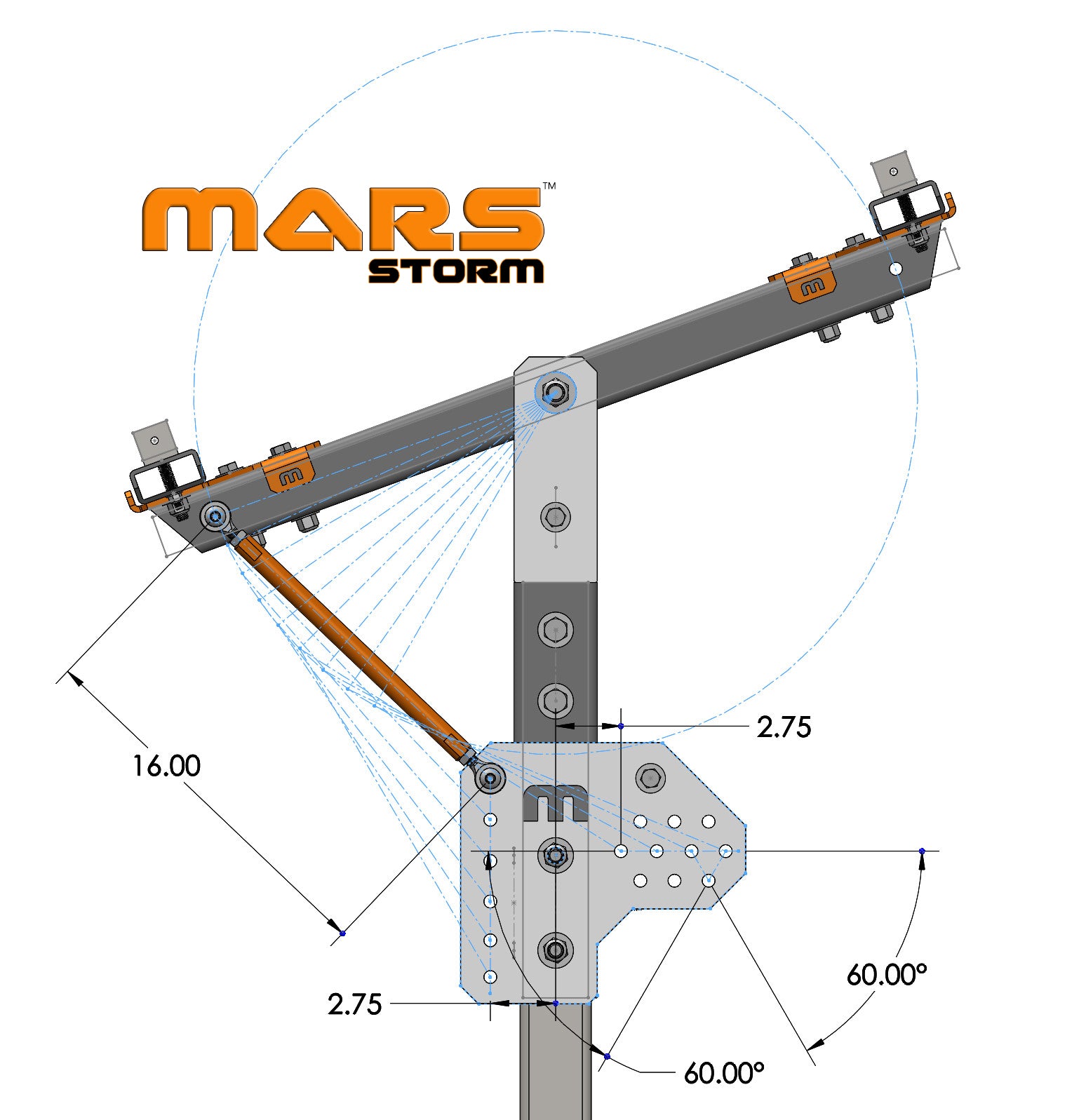

200 Ground Mount System - SnapNrack

The piers were deep. Ours has to survive hurricanes.

We don't get the full hurricane wind inland, probably 120mph gusts here, max.

I tried to rent an auger, none available, no rental places could tell me how long.

As we have lots of fence posts to replace, I just bought an auger and the related bits.