When I balance a new battery I start at 3.4V to rough out the work. Then in production I use 3.45V with a charging voltage of 55.2V.

To destroy the top balancing, try a value like 3.0V, you will see it is very effective.

,

@arzaman

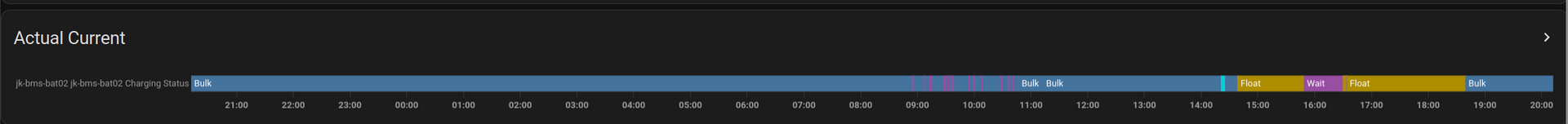

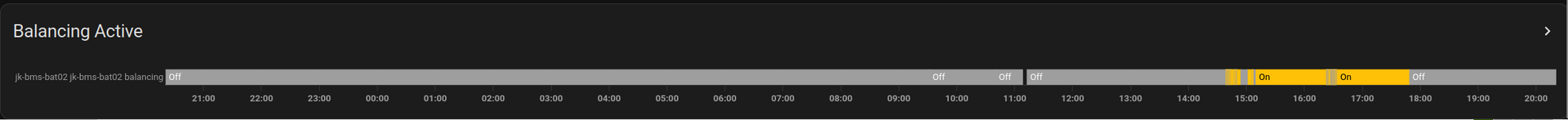

OK something weird is again going on. I didn't implement these measures yet though ...

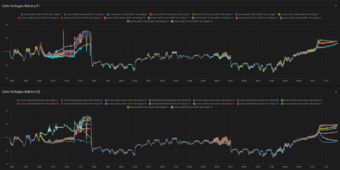

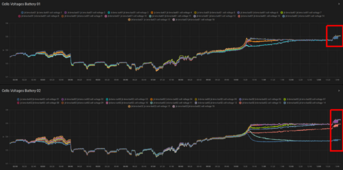

Ignore the left side of the picture around 17h45 ... I tried an OTA update, it got stuck (as usual), then inverter went "full power" (max voltage & current), and both batteries tripped ...

On the right side around 10h45, cell 11 is again behaving very weirdly ... I am not sure what to think ... A miswired balance lead would probably result in a cell going either to the "moon" (OVP) or to the "ground" (UVP). This is not happening ... But as current reduced (when cell 11 turquoise in the plot is "overtaken" by most others). So I'm tending to say it's probably a bad connection / bad cell (ESR is higher, thus current x ESR = voltage is higher during charging at "high" current, but NOT at low current), as

@Der_Hannes ands

@MrPablo said. The other consequence is of course less energy "reaches" the cell during charging, thus it needs to be "recharged" during the balancing process (which is never taking place fully right now).

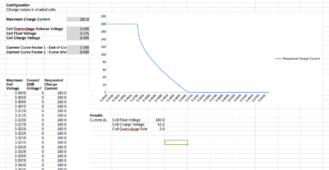

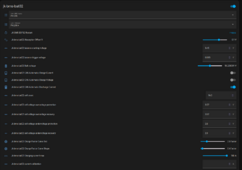

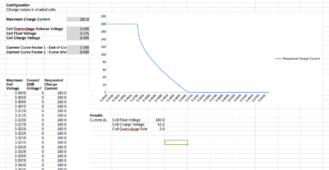

I updated Current Charge Control to 2.00 / 0.40 as below. This seems to make it much more smooth and stable. Thank you for the suggestion ! I think 1.0 was still too much, so I wanted to see how it would go with 0.40. Actually, battery 01 (the one behaving well), liked it quite a bit. Almost until the top of the charge it went full current, maybe only 40-50 A in the last minutes. This is perfect

.

On the other hand, I cannot say the same for the Charge Voltage Control.

Now I am again having +1A ... -1A in the battery oscillations. This is probably due to the fact that the "Absorbtion Offset V." Parameter gets "dropped" when the "Charging Status" changes from "Bulk" to "Balancing".

As a result it will not balance properly ...

So, on my side at least, I'll try to introduce another parameter "Balancing Offset V." Parameter, probably the same value as "Absorbtion Offset V.", but that I can tune via Home Assistant for now ...

I'll also have a look at the "End of bulk / balancing" conditions as I believe this contributes to the balancing never being done properly.

Besides this I'll make these parameters that can be changed, at least for testing:

float cell_uniformity = 1.0;

float cell_sensitivity = 1.8; // For more aggressive reponse, reduce this number.

float cell_bulk_v = (id(bulk_voltage).state / id(cell_count).state);

float cell_charge_knee_v = 3.400;

Same for these as well

float cv_min = 3.37;

float cv_max = 3.65;

Other issue (or feature ?): using the code here (instead of syssi esphome-jk-bms) my hostname / device name "jk-bms-bat02" is repeated 2 times for all of the sensors.

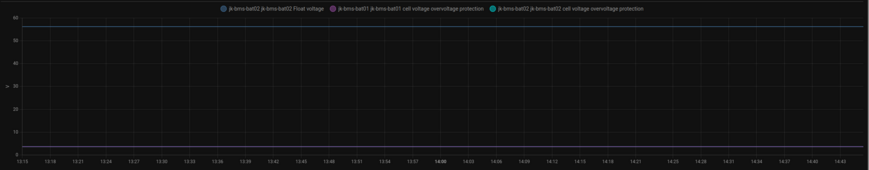

This is what I have in my Home Assistant Lovelace Dashboard, notice the difference between Battery 01 (syssi code) and Battery 02 (Sleeper 85 code):

YAML:

type: vertical-stack

cards:

- type: horizontal-stack

cards:

- type: history-graph

entities:

- entity: sensor.jk_bms_bat01_cell_voltage_1

- entity: sensor.jk_bms_bat01_cell_voltage_2

- entity: sensor.jk_bms_bat01_cell_voltage_3

- entity: sensor.jk_bms_bat01_cell_voltage_4

- entity: sensor.jk_bms_bat01_cell_voltage_5

- entity: sensor.jk_bms_bat01_cell_voltage_6

- entity: sensor.jk_bms_bat01_cell_voltage_7

- entity: sensor.jk_bms_bat01_cell_voltage_8

- entity: sensor.jk_bms_bat01_cell_voltage_9

- entity: sensor.jk_bms_bat01_cell_voltage_10

- entity: sensor.jk_bms_bat01_cell_voltage_11

- entity: sensor.jk_bms_bat01_cell_voltage_12

- entity: sensor.jk_bms_bat01_cell_voltage_13

- entity: sensor.jk_bms_bat01_cell_voltage_14

- entity: sensor.jk_bms_bat01_cell_voltage_15

- entity: sensor.jk_bms_bat01_cell_voltage_16

title: Cells Voltages Battery 01

hours_to_show: 24

- type: horizontal-stack

cards:

- type: history-graph

entities:

- entity: sensor.jk_bms_bat02_jk_bms_bat02_cell_voltage_01

- entity: sensor.jk_bms_bat02_jk_bms_bat02_cell_voltage_02

- entity: sensor.jk_bms_bat02_jk_bms_bat02_cell_voltage_03

- entity: sensor.jk_bms_bat02_jk_bms_bat02_cell_voltage_04

- entity: sensor.jk_bms_bat02_jk_bms_bat02_cell_voltage_05

- entity: sensor.jk_bms_bat02_jk_bms_bat02_cell_voltage_06

- entity: sensor.jk_bms_bat02_jk_bms_bat02_cell_voltage_07

- entity: sensor.jk_bms_bat02_jk_bms_bat02_cell_voltage_08

- entity: sensor.jk_bms_bat02_jk_bms_bat02_cell_voltage_09

- entity: sensor.jk_bms_bat02_jk_bms_bat02_cell_voltage_10

- entity: sensor.jk_bms_bat02_jk_bms_bat02_cell_voltage_11

- entity: sensor.jk_bms_bat02_jk_bms_bat02_cell_voltage_12

- entity: sensor.jk_bms_bat02_jk_bms_bat02_cell_voltage_13

- entity: sensor.jk_bms_bat02_jk_bms_bat02_cell_voltage_14

- entity: sensor.jk_bms_bat02_jk_bms_bat02_cell_voltage_15

- entity: sensor.jk_bms_bat02_jk_bms_bat02_cell_voltage_16

title: Cells Voltages Battery 02

hours_to_show: 24