A hard start improves the lifespan of the compressor because it reduces the time a compressor motor strains at startup. Has little if any benefit for a generator or inverter. Amps needed to start up do not change with a hard start.The same people who expressed to me their concerns about adverse effects of easy start on compressor life also install generator backup systems. They use hard starts on ac units that need to start on generators (of course that would not work with an inverter) They say a hard start does cause more initial stress, but the effect on lifetime is not measurable and they have many, many years of successful experience using them. They say the extended time periods at low voltage that an easy start invokes will result in higher temperatures in the compressor during the extended start and while it may turn out that after many, many years of experience the impact is also not measurable, they believe it will be.

Now, for my opinion, much like the medical field- if you don’t have the disease, don’t take the medicine or if you personally have no risk of problems with CoVid, don’t take the even tiny risk associated with the vaccine and any vaccine. The same goes for an AC unit, if you don’t need to start it offgrid, there probably is no benefit to justify the risk of an easy start.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Just installed some EasyStarts on 5 ton AC

- Thread starter Will Prowse

- Start date

But reducing the inverter size has zero influence to the amount of solar or the amount of battery needed for your loads… unless you are deciding weather or not the ac can be run on the solar… and that would increase the amount of solar needed.I need to see what the AC pulls in current but yes I realize the power consumption won’t change. I should have been more specific. I was thinking if I reduce the inverter size I reduce the amount of panels I need. A load is a load.

But reducing the inverter size has zero influence to the amount of solar or the amount of battery needed for your loads… unless you are deciding weather or not the ac can be run on the solar… and that would increase the amount of solar needed.

Yes I am strictly deciding if the ac can be run on the solar.

This is wise, calculate the energy consumed by ac, and add up all the kWh’s it will consume. Ac even on a small building is a massive additional load. Easily 4 times the amount of most every home consumption.Yes I am strictly deciding if the ac can be run on the solar.

Loads usually average out as heating - cooling - water heating - refrigeration (and freezing) - most of the rest of the loads are lumped together…

Ok i finally decided to do some math and put this old wives' tale to rest:They say the extended time periods at low voltage that an easy start invokes will result in higher temperatures in the compressor during the extended start and while it may turn out that after many, many years of experience the impact is also not measurable, they believe it will be.

4 ton compressor has 3.5 Kg of copper.

Specific heat capacity of copper = 1.46 J/(g*K)

J = 1.46 * (g*K)

J = 1.46 * 3500 * K

J = 5100 * K

convert to watt hours:

Wh = 5100/3600 * K

Wh = 1.42 * K

so it will take 1.42 watt hours to heat 4 ton compressor copper winding by 1 Kelvin or 1°C.

Easy start says it takes 0.5 seconds to start a compressor with easy start versus 0.1 sec without.

It takes 36A for 0.5 sec. Then:

240V * 36A / (3600 / 0.5) = 1.2 watt hours.

Finally calculating heat rise in copper winding when using easy start:

1.2 / 1.42 = 0.84 degrees C winding temp rise per start.

This is the same "don't place battery on concrete" type of old tale.

Edit: Actual temp rise with easystart may be 50% less than calculated above.

Last edited:

This is wise, calculate the energy consumed by ac, and add up all the kWh’s it will consume. Ac even on a small building is a massive additional load. Easily 4 times the amount of most every home consumption.

Loads usually average out as heating - cooling - water heating - refrigeration (and freezing) - most of the rest of the loads are lumped together…

Yeah hopefully I’m not causing more confusion than benefit. Essentially I have 2200W of solar laying around. I want to throw that at my total monthly kWh. I’m trying to optimize my setup so what is the biggest load I can power off solar, during the day because I’m going batteryless, rhetorically speaking. Is it the ac unit, water heater, or only the receptacles in a spare bedroom. If that’s the case I’ll know it’s probably not worth going through the trouble of incorporating my panels and may be better off selling the panels. I don’t want my ROI to be 8+ years haha.

sunshine_eggo

Happy Breffast!

This is the same "dont place battery on concrete" type of old tale.

I still run into this blatant stupidity.

MajicDiver

Solar Enthusiast

A generator is a rotating machine and has inertia- with hard start on an AC unit, the AC is running before any generator protection has time to activate, you can use a smaller generator.A hard start for generator use seems counterproductive

MajicDiver

Solar Enthusiast

Well done, thanks!Ok i finally decided to do some math and put this old wives' tale to rest:

4 ton compressor has 3.5 Kg of copper.

Specific heat capacity of copper = 1.46 J/(g*K)

J = 1.46 * (g*K)

J = 1.46 * 3500 * K

J = 5100 * K

convert to watt hours:

Wh = 5100/3600 * K

Wh = 1.42 * K

so it will take 1.42 watt hours to heat 4 ton compressor copper winding by 1 Kelvin or 1°C.

Easy start says it takes 0.5 seconds to start a compressor with easy start versus 0.1 sec without.

It takes 36A for 0.5 sec. Then:

240V * 36A / (3600 / 0.5) = 1.2 watt hours.

Finally calculating heat rise in copper winding when using easy start:

1.2 / 1.42 = 0.84 degrees C winding temp rise per start.

This is the same "don't place battery on concrete" type of old tale.

MajicDiver

Solar Enthusiast

So, what’s the reasoning behind that one?This is the same "don't place battery on concrete" type of old tale.

Hedges

I See Electromagnetic Fields!

- Joined

- Mar 28, 2020

- Messages

- 20,812

The Concrete Truth About Batteries Stored on Concrete

Have you heard the one about batteries discharging when stored on concrete? Apparently, some people have taken to storing 12V batteries—the kind used in electric wheel chairs and emergency lighting systems—on wooden shelves to maximize their life expectancy. Is there a spark of truth to this or...

www.mcgill.ca

Texas-Mark

Solar Addict

- Joined

- Aug 4, 2021

- Messages

- 1,297

A generator is a rotating machine and has inertia- with hard start on an AC unit, the AC is running before any generator protection has time to activate, you can use a smaller generator.

Not just talking about immediate protection, a smaller generator will bog down and then may cause something to trip. I know mine grunts and lights dim when the compressor kicks in.

If you say you can use a smaller generator with a hard start, why are people using a soft start specifically to use a smaller generator?

RCinFLA

Solar Wizard

- Joined

- Jun 21, 2020

- Messages

- 3,565

What Easystart document says normal startup time is 0.1 seconds?Easy start says it takes 0.5 seconds to start a compressor with easy start versus 0.1 sec without.

That is just plain wrong.

Easystart targets about 0.5 seconds of start time during the training process by backing down the voltage level during ramp up, which yields lower starting surge current. It requires the hard start cap to do this.

Typical single phase induction AC motor with just a Run capacitor is about 0.4 seconds.

When a hard start kit is added, the startup period will be reduced to about 0.2 seconds due to auxiliary winding getting closer to 90 degrees phase shift which increases motor startup torque reducing spin up time.

Wiring resistance to main breaker panel increases startup voltage slump during startup surge current, increasing startup time.

The normal current/heat protection Klixon in the compressor will trip due to normal startup surge current if it lasts longer than about 1 second.Not just talking about immediate protection, a smaller generator will bog down and then may cause something to trip. I know mine grunts and lights dim when the compressor kicks in.

If you say you can use a smaller generator with a hard start, why are people using a soft start specifically to use a smaller generator?

Hard start kits do not reduce start up surge current. They do reduce startup surge time period by about half.

Last edited:

MajicDiver

Solar Enthusiast

Remember, at your request I am simply repeating the explanation I received from a very experienced and respected company in our area who has been doing the work longer than I’ve been alive.If you say you can use a smaller generator with a hard start,

It’s logical though, when very fast large load hits a generator (off grid) it momentarily drops in speed and the inertia of the generator supplies the load until it trips on low frequency or something. If you make the spike higher but fast it doesn’t trip (of course there are limits), make it lower but longer and it may trip. This is one of fundamental things about our grid that makes it robust, the massive inertia of the thousands of turbine-generators out here make it robust enough to ride out a lot of events without going down, add too much solar and you start getting blackouts.

What Easystart document says normal startup time is 0.1 seconds?

That is just plain wrong.

From this video.

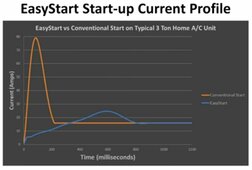

If we estimate area under the curve for easy start then average start current is approximately 16A for 0.8 seconds. Even better.

Hedges

I See Electromagnetic Fields!

- Joined

- Mar 28, 2020

- Messages

- 20,812

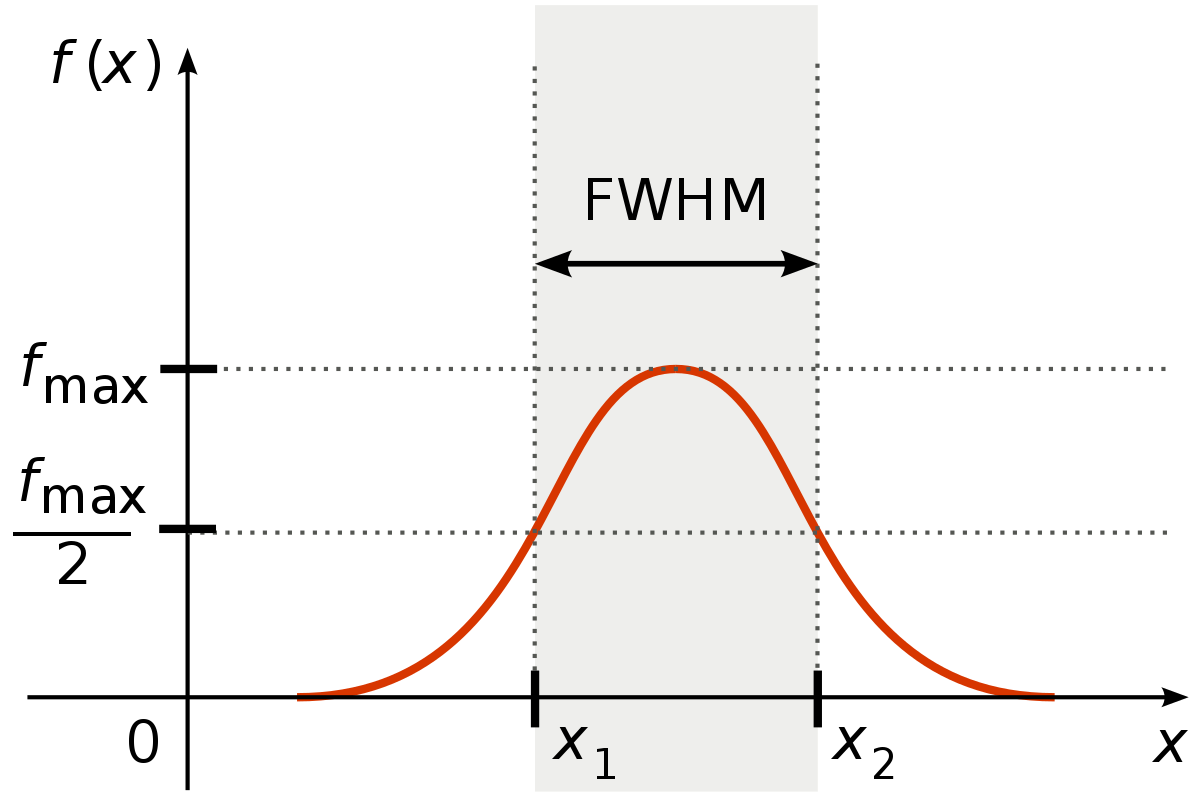

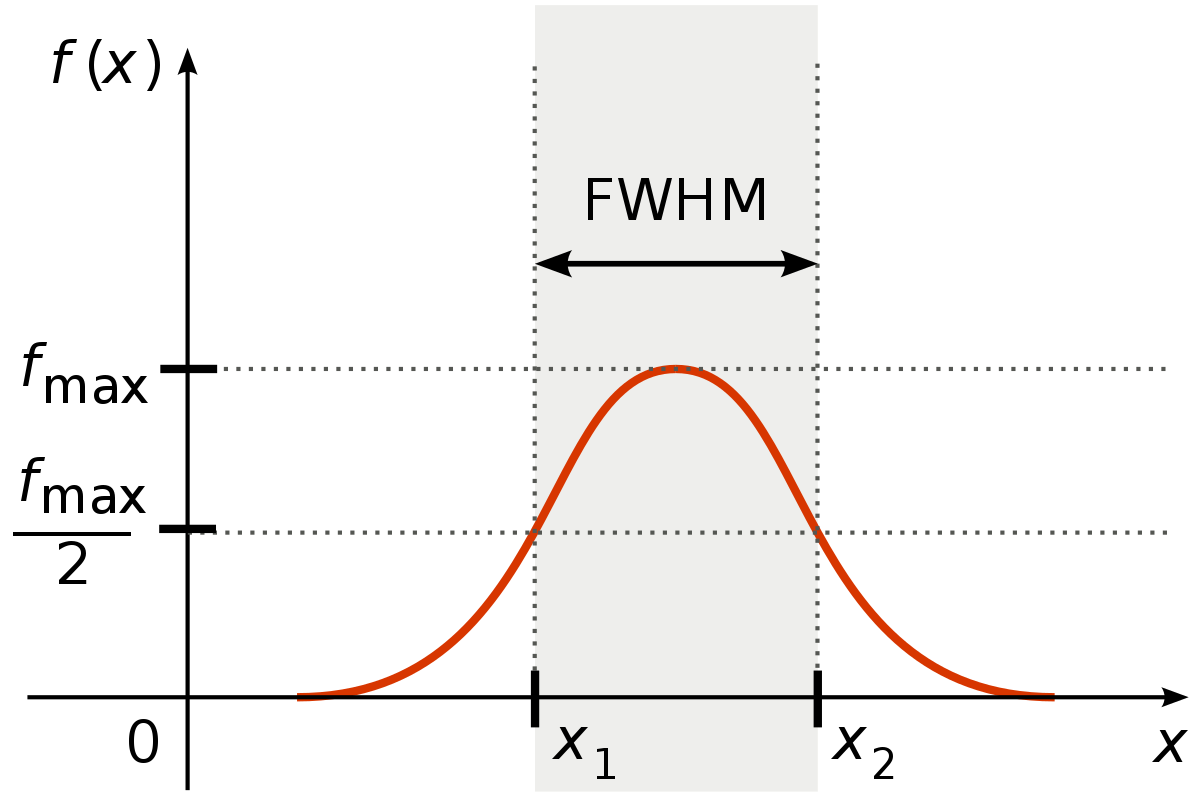

Full Width Half Maximum 0.1 seconds

That's one way to measure a peak, or describe resolution.

Common in many fields. But for inverters, maybe we want to know when the surge is over, current draw reaches steady-state.

en.wikipedia.org

en.wikipedia.org

That's one way to measure a peak, or describe resolution.

Common in many fields. But for inverters, maybe we want to know when the surge is over, current draw reaches steady-state.

Full width at half maximum - Wikipedia

RCinFLA

Solar Wizard

- Joined

- Jun 21, 2020

- Messages

- 3,565

Time period is wrong.From this video.

View attachment 205852

If we estimate area under the curve for easy start then average start current is approximately 16A for 0.8 seconds. Even better.

Shape is not correct.

Marketeers have gotten creative again.

Diagram from Copeland with little interconnect wiring resistance resulting in shorter start periods.

Curve of Emerson SecureStart softstarter. Again, with little wiring resistance that increases start period.

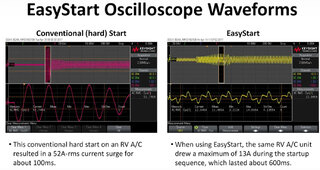

This image is from Easystart web site comparing a hard start kit to Easystart softstarter.

Last edited:

@RCinFLA Exact curve shapes don't really matter. From calculations above you can see that start up temp rise is irrelevant for both conventional start and easy start. Winding thermal mass easily absorbs start up energy into relatively tiny temp rise. I just wanted to show that concern over start up heat rise is totally irrelevant. Edit: great charts as usual!

Hedges

I See Electromagnetic Fields!

- Joined

- Mar 28, 2020

- Messages

- 20,812

The actual current is a sine wave.

My scope doesn't have "track and trend"; if it did might be able to graph an envelope like that.

The envelope I do see lasts about 150 ms seconds for a window A/C.

diysolarforum.com

diysolarforum.com

My scope doesn't have "track and trend"; if it did might be able to graph an envelope like that.

The envelope I do see lasts about 150 ms seconds for a window A/C.

Is 600w enough

I plan on putting 600w of solar panels on the roof of a small camper. The Panels will be able to tilt so I can get as much power as I can. My main use is to run a 5000 BTU AC tha draws 450w in the summer and a 500w space heater in the winter & a few little items like phones, tablets and led...

I've posted that video on other threads. Anyone interested in the technical aspects and benefits of the EasyStart should watch it.From this video.

View attachment 205852

If we estimate area under the curve for easy start then average start current is approximately 16A for 0.8 seconds. Even better.

Similar threads

- Replies

- 5

- Views

- 704

- Replies

- 8

- Views

- 1K

- Replies

- 2

- Views

- 114

- Replies

- 8

- Views

- 828