Interesting, thanks to share.

Based on this, It's clear that I would never spend money, time and effort to try to save a bit of life over a long period of time.

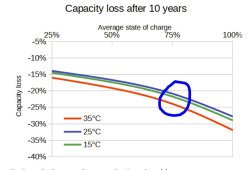

Imagine, if you use your cells wisely and discharge them at an average of 75% you could save around 4% of capacity over 10 years. It's nothing and a cheap BMS will probably destroy it before 10 years.

Take a look at the cells available 10 years ago (price, energy density, cycle life) and try to imagine the cells available in 10 years (price↓, energy density↑, cycle life↑). You will certainly be tempted to add or replace it with a low cost/high cycle life new battery in 10 years.

And please don't tell me you are living in a place where it's temperature is always 35°C. Some place are hot, like on the edge of the Great Sandy Desert, but most of the year (night, winter), the temperature is lower. So, really, add all this stuff to save ridiculous amount of life out of the cells is way more about interesting experiments than real needs.

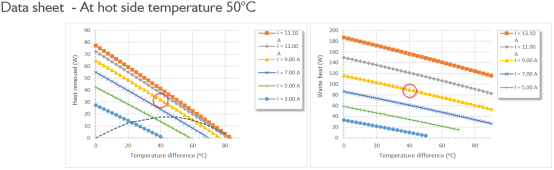

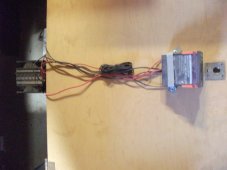

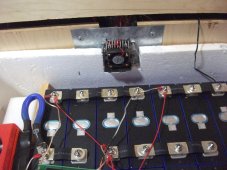

I'm all to extend life of things to reduce waste and be gentle on new resources extraction, but it's clearly not the case here as those mini split/evaporative cooler have their own impact (resources, energy, garbage).

View attachment 140814