PreppenWolf

Solar Addict

- Joined

- Oct 10, 2022

- Messages

- 930

I'd love to see 500h+ cells for future builds. I'd like to see 96V inverters too.

Damn I just bought 32 new LF304 cells.

EVE Launches New Generation LF560K Energy Storage Battery

Based on CTT technology, the LF560K battery can reduce the total system cost, has a large capacity of 560Ah, can store 1.792kWh of energy in a single battewww.evlithium.com

Should be for sale this year.

Oh that makes more sense. I simply had it backwards in timeline.@G00SE 280Ah has been around for longer that the 304Ah ones. 280 goes back to 2017 if I remember correctly. I believe (and this is just my thinking) is that the 304 is the result of a new line at EVE, while the 280 kept being developed in a different line. We also see the 560 now - which is probably spun off from the 280 line.

Damn I just bought 32 new LF304 cells.

But of course twice the capacity means twice the size/weight and probably (almost ?) twice the cost.

In my case the main argument for LF304 was availability and the double threaded terminals.When I was looking a while back the 304's seemed to be the same size as the 280, I was of the impression that a technology improvement created a modicum of density improvement. Someone feel free to enlighten further. I would have expected a '608' as the double size cell. At some point it get's a little ugly with very large heavy low voltage cells. When you need 16 to get to 48V it requires a lot of storage space / volume.

I can't find a spec sheet on the 560 anywhere. Lots of pictures lacking anything to allow for a size reference.When I was looking a while back the 304's seemed to be the same size as the 280, I was of the impression that a technology improvement created a modicum of density improvement. Someone feel free to enlighten further. I would have expected a '608' as the double size cell. At some point it get's a little ugly with very large heavy low voltage cells. When you need 16 to get to 48V it requires a lot of storage space / volume.

Is anyone in this thread thinking long term? There will be a glut of cells now and then prices will sky rocket as they get either old or there is less production?

They should make it smaller. They’d sell moreAnd of course a display box

View attachment 199528

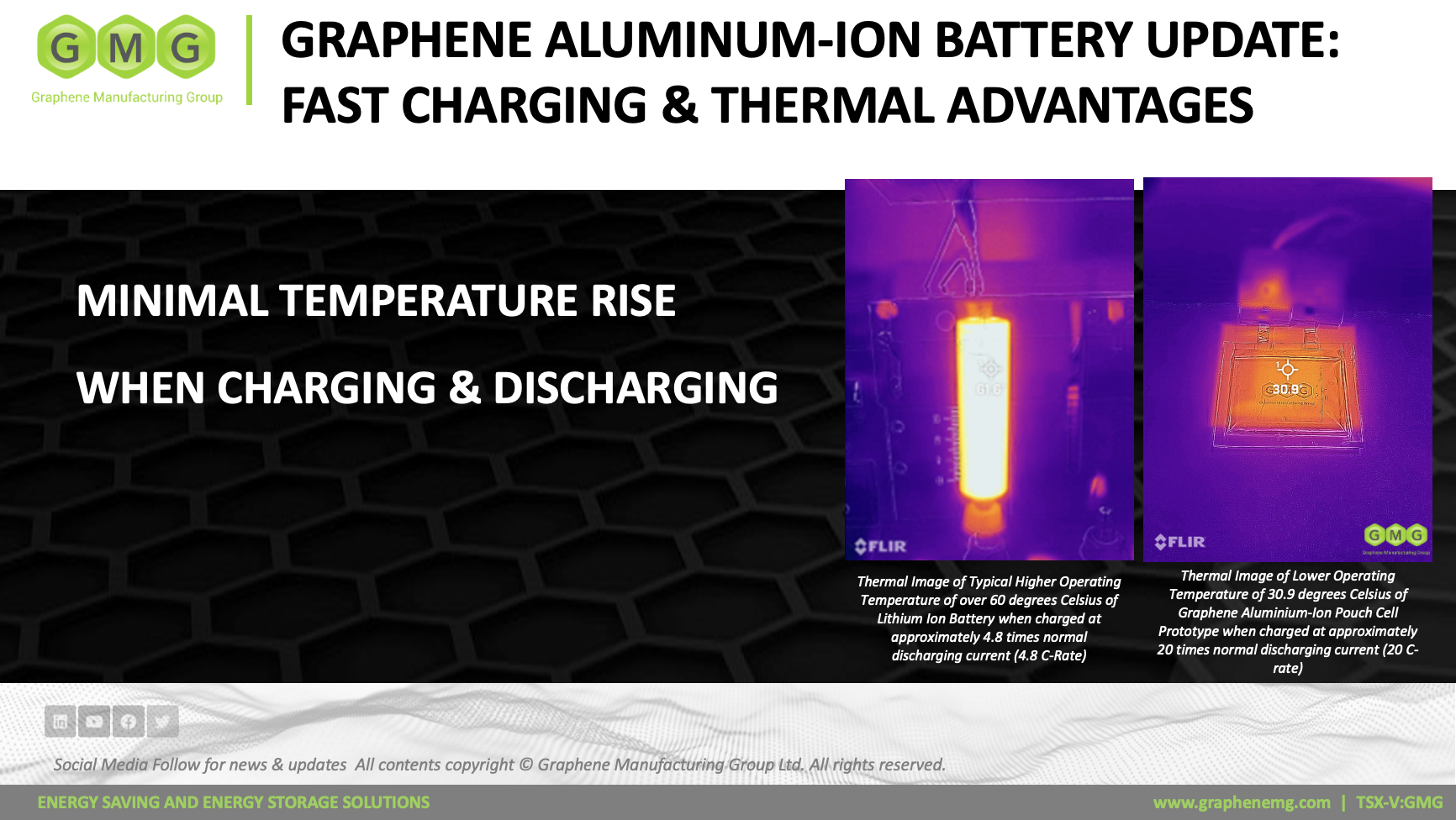

I don't think this product actually exists at this point. "We gonna make one, I promise"

I'd love to see 500h+ cells for future builds. I'd like to see 96V inverters too.

I also think that after this year’s price dip, the longer term factors will drive prices back upwards. Timing a purchase decision correctly will be a good trick to pull off.Is anyone in this thread thinking long term? There will be a glut of cells now and then prices will sky rocket as they get either old or there is less production?

Well, SHIT.

What does moving them up out of the low voltage category do with certs if anything?

Makes the DC side a lot more dangerous for DIY for sure.

Sure. But higher insulation levels. Same as in MMC Converters and HVDC stations. "Plastic" is typically cheaper than copper, so the logic is valid to some extent.Voltage needs to go up towards EV car battery pack voltages to help lower copper requirements, lower volumes of bulk systems, further press costs down and create more competitive options. Among other things, like reducing line losses for DC transport.

Higher voltage safety exists. We just need to grow with it. All the reasons we aren't using 12V or 24V as primary in home systems are reasons to keep going up further. Higher voltage means less amps.

Voltage needs to go up towards EV car battery pack voltages to help lower copper requirements, lower volumes of bulk systems, further press costs down and create more competitive options. Among other things, like reducing line losses for DC transport.

Higher voltage safety exists. We just need to grow with it. All the reasons we aren't using 12V or 24V as primary in home systems are reasons to keep going up further. Higher voltage means less amps.

If common insulation can manage 600v without blinking an eye it’s only a matter of time 96v is the new 48v.Sure. But higher insulation levels. Same as in MMC Converters and HVDC stations. "Plastic" is typically cheaper than copper, so the logic is valid to some extent.

But then you'll have your battery pack sitting on a 500mm (or more) tall electrical insulator. And your communication system/controller and power supplies will need to be isolated accordingly too.

Fair enough, you're not planning an HVDC station yet ?If common insulation can manage 600v without blinking an eye it’s only a matter of time 96v is the new 48v.

Just think 1 pack of 32 560ah cells, sure she’ll weigh more than twoton Tanya you met at the bar last nights but, that’s a one bank whole house setup.

If common insulation can manage 600v without blinking an eye it’s only a matter of time 96v is the new 48v.

Just think 1 pack of 32 560ah cells, sure she’ll weigh more than twoton Tanya you met at the bar last nights but, that’s a one bank whole house setup.