Samsonite801

Solar Wizard

- Joined

- Oct 15, 2020

- Messages

- 2,994

I FINALLY got around to building my wall and hanging my inverters in the last couple weeks. I never did like the PV inputs being MC4 connectors on the bottom of the units, because it didn't lend itself well to the idea of going all conduit.

So after thinking on it some, I noticed that the LV6548's come with these nifty little extension boxes, but they were made to be screwed onto the bottom-right end of the inverters, to extend the battery terminal conduits (for SOME reason unknown to me).

So I got to thinking, maybe I could just use those boxes, and fashion them to the lower-left end of the inverters, right under the PV inputs, and get rid of the MC4's, and just put spade connectors right on the ends of my PV wires and plug them directly into the input boards.

So far the idea is working out good, haven't gotten to the wiring yet, but the box fits, there was one threaded hole that happened to be there already, just had to drill 2 more holes, put nuts/screws on them, and use my die grinder to notch the upper-right corner of the box so it would clear the 1" conduit fitting to the right of it.

Anyways, in case anyone with the LV6548's wants to try it, here are some pics...

Mockup with boxes at lower-left corner sitting there to test fit:

Permanently removed the old MC4 connector mounting plate:

Drilled 2 holes, one on each side, right side already had one suitable threaded hole that happened to line up perfectly to where I wanted the box to sit, some minor notching was needed around the box's flange mount to clear the 1" conduit to right of box:

Can't see the notching work very well here, but it is mostly on the flange near where the screws hold the flange to inverter case, and a little notch on the corner of the box itself above the cover plate flange mount:

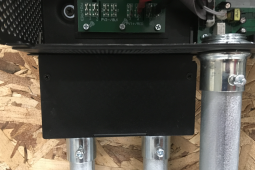

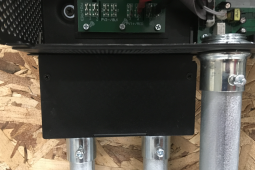

You can see the two screws/nuts I added in, and if you look close behind the right-side screw/nut, you can see the threaded screw hole that just happened to line up already (it's the left-side screw for the factory cover plate over the inverter sync board I/O plugs, which you remove anyways for multiple inverter stacking). It was nice, because I put in the factory style screw into that hole, and it held the box in perfect spot to line up the box in perfect position to drill the other two holes:

Different angle:

Cover plate notched slightly too (upper-right corner):

Finished product (not including wiring):

Now you can have conduit on every wire run with your LV6548's, took under an hour to do and the boxes are already included with them, just need some tiny nuts/screws (countersink style)...

So after thinking on it some, I noticed that the LV6548's come with these nifty little extension boxes, but they were made to be screwed onto the bottom-right end of the inverters, to extend the battery terminal conduits (for SOME reason unknown to me).

So I got to thinking, maybe I could just use those boxes, and fashion them to the lower-left end of the inverters, right under the PV inputs, and get rid of the MC4's, and just put spade connectors right on the ends of my PV wires and plug them directly into the input boards.

So far the idea is working out good, haven't gotten to the wiring yet, but the box fits, there was one threaded hole that happened to be there already, just had to drill 2 more holes, put nuts/screws on them, and use my die grinder to notch the upper-right corner of the box so it would clear the 1" conduit fitting to the right of it.

Anyways, in case anyone with the LV6548's wants to try it, here are some pics...

Mockup with boxes at lower-left corner sitting there to test fit:

Permanently removed the old MC4 connector mounting plate:

Drilled 2 holes, one on each side, right side already had one suitable threaded hole that happened to line up perfectly to where I wanted the box to sit, some minor notching was needed around the box's flange mount to clear the 1" conduit to right of box:

Can't see the notching work very well here, but it is mostly on the flange near where the screws hold the flange to inverter case, and a little notch on the corner of the box itself above the cover plate flange mount:

You can see the two screws/nuts I added in, and if you look close behind the right-side screw/nut, you can see the threaded screw hole that just happened to line up already (it's the left-side screw for the factory cover plate over the inverter sync board I/O plugs, which you remove anyways for multiple inverter stacking). It was nice, because I put in the factory style screw into that hole, and it held the box in perfect spot to line up the box in perfect position to drill the other two holes:

Different angle:

Cover plate notched slightly too (upper-right corner):

Finished product (not including wiring):

Now you can have conduit on every wire run with your LV6548's, took under an hour to do and the boxes are already included with them, just need some tiny nuts/screws (countersink style)...

Last edited: