I had posted this in the beginners section already, but did not get a response. Maybe this forum is better.

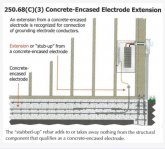

I moved my panels from roof-top to a concrete platform, with lots of rebar in it. I'm estimating 10,000 ft of 5/8" rebar that is all connected. The rack structure is 80% steel and 20% aluminum and is connected to that rebar.

Do I need to ground all the panels, the same way they were grounded on the roof, and do I need to run the ground back to the inverter? Aren't they already grounded? 3rd option, drive a new rod at the new location, and ground to that rod.

Here is the link to my other post, maybe I was too wordy.

I moved my panels from roof-top to a concrete platform, with lots of rebar in it. I'm estimating 10,000 ft of 5/8" rebar that is all connected. The rack structure is 80% steel and 20% aluminum and is connected to that rebar.

Do I need to ground all the panels, the same way they were grounded on the roof, and do I need to run the ground back to the inverter? Aren't they already grounded? 3rd option, drive a new rod at the new location, and ground to that rod.

Here is the link to my other post, maybe I was too wordy.