Hi,

I am looking to connect two battery packs in parallel and would like to keep BMS communication with the inverter via CAN instead of just voltage/current. I saw that pylon is doing this via LV-HUB module where serial strings connect in parallel and their BMSes are connecting to this hub which in turn is connecting to the inverter.

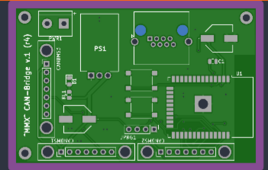

Since I am an engineer I am considering building one myself I already built JK-BMS to Growatt CAN L52 protocol converter using and enhancing code which is already on github and it is working great.

I already built JK-BMS to Growatt CAN L52 protocol converter using and enhancing code which is already on github and it is working great.

Looking at this device I assume LV-HUB is doing the following:

If anyone with experience could confirm the fact that such devices basically are averiging out data across the battery banks and since each has its own BMS providing safety to cells it seems logical. Otherwise interters would be aware of multiple batteries and at least with victron they seem not to be.

Regards,

M

I am looking to connect two battery packs in parallel and would like to keep BMS communication with the inverter via CAN instead of just voltage/current. I saw that pylon is doing this via LV-HUB module where serial strings connect in parallel and their BMSes are connecting to this hub which in turn is connecting to the inverter.

Since I am an engineer I am considering building one myself

Looking at this device I assume LV-HUB is doing the following:

- Each BMS battery port of LV-HUB comes with its own CAN driver and terminations on both ends. In fact it is likely implementing multiple CAN busses internally one per parallel battery module. The reason why I think so is that I have nowhere found within pylon LV CAN protocol battery ID to distinguish reply origin to 0x305 request (unless dip switches operate this at can controller level transparently to the protocol itself). Without battery ID on a shared bus there's no telling which unit sent it. Also more likely if one string would develop and issue and the other did not, the outcome should still be an alarm and battery system shutdown.

- Also LV-HUB is likely sending consolidated data to the inverter. I.e. with Victron you don't see individualpacks (not even strings) for such configuration but just aggregated set of data like for one large pack.

- Therefore I assume LV-HUB is performing calculation on numeric data like battery voltages, currents, SOC as "mean" for the entire battery module with parallel strings and for bit data like alarms as OR (boolean algebra) for of each of parallel strings.

If anyone with experience could confirm the fact that such devices basically are averiging out data across the battery banks and since each has its own BMS providing safety to cells it seems logical. Otherwise interters would be aware of multiple batteries and at least with victron they seem not to be.

Regards,

M