fmeili1

Solar Enthusiast

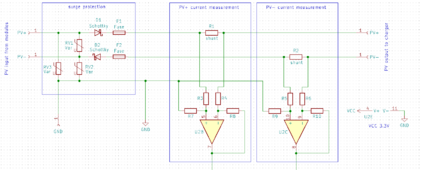

I was thinking about whether you could build an AFDD and GFDD detector yourself that is contactless and only operated using a current transformer (this is only about detection, not circuit disconnect after detection, so no AFCI and GFCI devices).

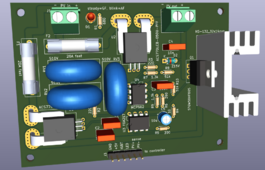

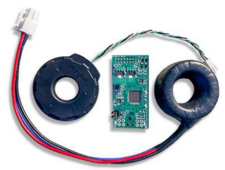

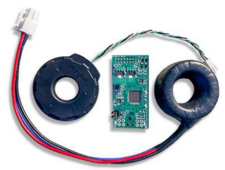

After some research, I found the MNHBB-AFGF sensor from MidNiteSolar which is doing exactly what I want. Unfortunately, it only works with the corresponding MidNiteSolar MPPT chargers. I haven't been able to find a generic AF/GF detector for PV (DC) yet. Here is a picture of this MidNite module.

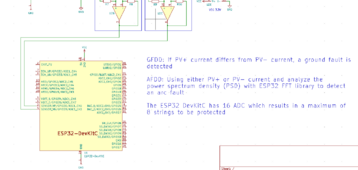

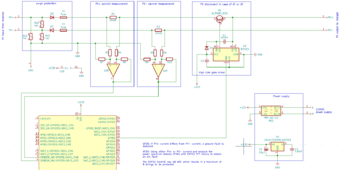

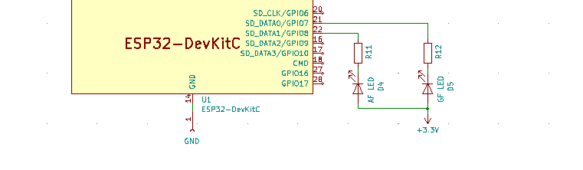

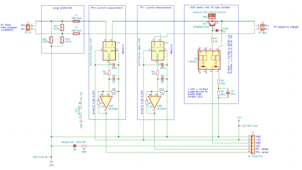

After further research, I came across the paper "Arc-Faults Detection in PV Systems by Measuring Pink Noise With Magnetic Sensors". The process doesn't look that complicated and should actually be able to be implemented with an Arduino, for example (FFT and some arithmetic to determine the pink noise). The covered DC voltage and current range from 50V to 300V and 6A to 30A is a perfect fit for typical home PV systems.

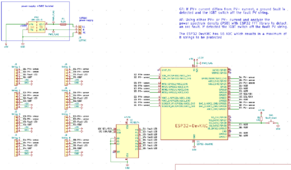

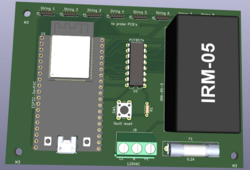

The GF detection could be determined relatively easily, as with the MidNite module, using current delta with 2 CTs (one around PV+ and one around PV-). 2 CT's would then be necessary per PV string to cover both AFDD and GFDD. An Arduino could probably control multiple strings (CT's).

Such a device would be very helpful for people like me who own AIO devices that do not have integrated AF and GF detection/disconnects (e.g. EG4-6500EX). If an AF or GF was detected you could use it to disconnect the PV strings with external mechanisms, e.g. either with remotely controlled contactors or with, for example, Tigo TS4-A-2F.

Instead of CTs, possibly a coreless compact and cheap tunnel magnetoresistance (TMR) which are mentioned in the article and are attached to the PV cables on the insulation, could be used. I think the accuracy of the sensor and also the FFT calculation resolution needs not to be very exact and fast to just achieve an ARC detection - but I'm not sure.

In addition to the software challenges (FFT etc.), I see two additional potential problems:

Has anyone ever heard of a project like this?

After some research, I found the MNHBB-AFGF sensor from MidNiteSolar which is doing exactly what I want. Unfortunately, it only works with the corresponding MidNiteSolar MPPT chargers. I haven't been able to find a generic AF/GF detector for PV (DC) yet. Here is a picture of this MidNite module.

After further research, I came across the paper "Arc-Faults Detection in PV Systems by Measuring Pink Noise With Magnetic Sensors". The process doesn't look that complicated and should actually be able to be implemented with an Arduino, for example (FFT and some arithmetic to determine the pink noise). The covered DC voltage and current range from 50V to 300V and 6A to 30A is a perfect fit for typical home PV systems.

The GF detection could be determined relatively easily, as with the MidNite module, using current delta with 2 CTs (one around PV+ and one around PV-). 2 CT's would then be necessary per PV string to cover both AFDD and GFDD. An Arduino could probably control multiple strings (CT's).

Such a device would be very helpful for people like me who own AIO devices that do not have integrated AF and GF detection/disconnects (e.g. EG4-6500EX). If an AF or GF was detected you could use it to disconnect the PV strings with external mechanisms, e.g. either with remotely controlled contactors or with, for example, Tigo TS4-A-2F.

Instead of CTs, possibly a coreless compact and cheap tunnel magnetoresistance (TMR) which are mentioned in the article and are attached to the PV cables on the insulation, could be used. I think the accuracy of the sensor and also the FFT calculation resolution needs not to be very exact and fast to just achieve an ARC detection - but I'm not sure.

In addition to the software challenges (FFT etc.), I see two additional potential problems:

- With non-isolated inverters (e.g. EG4-6500EX) there is an AC-like ripple signal on the PV lines, which could interfere with the determination of pink noise.

- The PVRSS system from Tigo uses communication over powerline to control of the remote switches (e.g. TS4-A-2F), which itself is coupled into the PV line using CTs. This signal could overlap with the ARC detection and possibly have a negative impact on the detection.

Has anyone ever heard of a project like this?