D

Deleted member 91418

Guest

While at work, I had a strange thought come to mind...

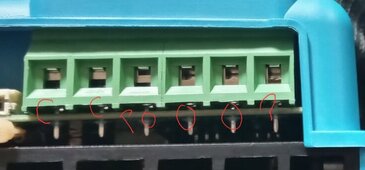

I had a Victron 100/20 that didn't work out well before, as some may remember. It was due to the terminals they use and why they wouldn't hold cables down. Since then I've seen some other Victrons which require 6AWG cables, however, I've never heard of such MC4 or PV wiring that large. My question is... how do you get your PV wires (most are 10AWG) into the Victron and not have them fall out? I was having a brain-spasm and thought:

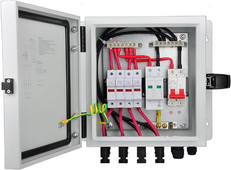

...if one array was brought down to it's own + and - busbar where it then attached to 6AWG cables, going into the Victron, would that work?

Let me know what you guys think! I personally won't try it, but the concept has been nagging my attention.

I still believe screws with washers are a much better connection method than what (nearly) all MPPT's use.

I had a Victron 100/20 that didn't work out well before, as some may remember. It was due to the terminals they use and why they wouldn't hold cables down. Since then I've seen some other Victrons which require 6AWG cables, however, I've never heard of such MC4 or PV wiring that large. My question is... how do you get your PV wires (most are 10AWG) into the Victron and not have them fall out? I was having a brain-spasm and thought:

...if one array was brought down to it's own + and - busbar where it then attached to 6AWG cables, going into the Victron, would that work?

Let me know what you guys think! I personally won't try it, but the concept has been nagging my attention.

I still believe screws with washers are a much better connection method than what (nearly) all MPPT's use.