Consumerbot3418

Fitting square pegs into round holes... for fun?

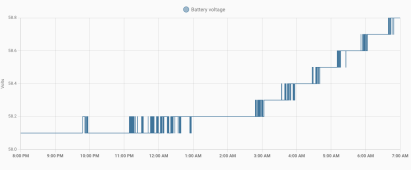

I bought a DC Solar trailer from a bankruptcy auction, and it has a pair of 48V GNB Tubular LMX batteries on board, wired in parallel. When I took possession, I took readings of individual cell voltages (all were fairly close), and topped off the water. Then it just sat unused, with the Midnite using onboard PV to keep the batteries in float for about 6 months, with some intermittent use charging an EV. During that time, I also ran equalization using the on-board PV.

I finally got around to using the trailer (and batteries) to power our house, and it looks like there's a lot of missing capacity. I took SG readings, and found that within each battery, most cells were pretty close, with just a few that were lower than the others by .005+. However, between the two batteries, the SG readings of one battery are significantly higher (over .01) than the other. I've also noticed that all cells in the battery with higher SG readings has already lost water down to the plates.

I'd expected these batteries to be in similar condition, since they spent their lives installed in parallel, but it seems they're quite imbalanced.

I'd like to locate and resolve the source of the imbalance (assuming it's external), and systematically refurbish the batteries as best I can. I have a DC clamp meter and a bench power supply that can do 5 amps at 60V.

Any ideas about figuring out the cause of the imbalance? I know I could apply a load or charge current and see the difference, but how could I isolate the cause? Power from the batteries to/from the inverters via welding cable to a pair of 350A Anderson connectors that combine to a single. I noticed the Midnite charge controller is wired directly to the positive battery terminal of the battery that has lower SG readings. Maybe I should start with eliminating that wire?

I'd also welcome any advice about refurbishing old forklift batteries. After a series of equalizations has been performed, and no more raise of SG readings, would it be appropriate to add battery acid to cells that indicate lower than the others?

I finally got around to using the trailer (and batteries) to power our house, and it looks like there's a lot of missing capacity. I took SG readings, and found that within each battery, most cells were pretty close, with just a few that were lower than the others by .005+. However, between the two batteries, the SG readings of one battery are significantly higher (over .01) than the other. I've also noticed that all cells in the battery with higher SG readings has already lost water down to the plates.

I'd expected these batteries to be in similar condition, since they spent their lives installed in parallel, but it seems they're quite imbalanced.

I'd like to locate and resolve the source of the imbalance (assuming it's external), and systematically refurbish the batteries as best I can. I have a DC clamp meter and a bench power supply that can do 5 amps at 60V.

Any ideas about figuring out the cause of the imbalance? I know I could apply a load or charge current and see the difference, but how could I isolate the cause? Power from the batteries to/from the inverters via welding cable to a pair of 350A Anderson connectors that combine to a single. I noticed the Midnite charge controller is wired directly to the positive battery terminal of the battery that has lower SG readings. Maybe I should start with eliminating that wire?

I'd also welcome any advice about refurbishing old forklift batteries. After a series of equalizations has been performed, and no more raise of SG readings, would it be appropriate to add battery acid to cells that indicate lower than the others?