fmeili1

Solar Addict

Finally I've finished the work on the active mini split cooling for the AIO's. Now I hope that the fan's will never speed up to full speed anymore with the modded temperature controlled fans.

--------------

--------------

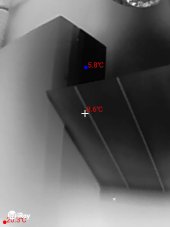

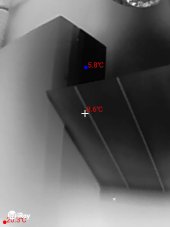

The 9,000BTU concealed ducted indoor unit is more than enough to cool the system down and it's very energy efficient (about 700W). When I have an ambient of 20°C in the garage, I measure between 5-8°C on the AIO cold air inlets. Looking forward how it will behave when we will have 120 Fahrenheit here in the desert in the next summer with full working MPPT chargers...

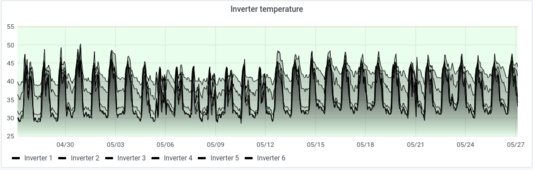

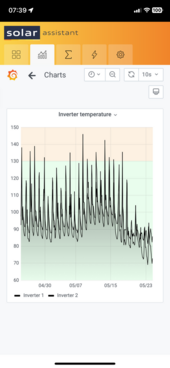

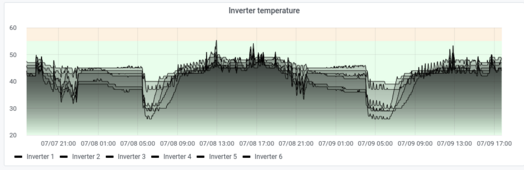

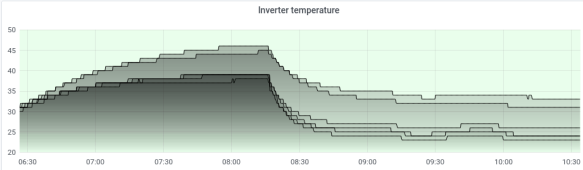

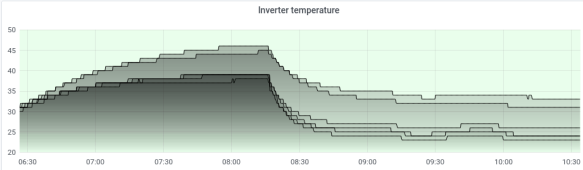

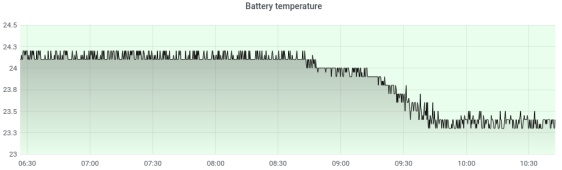

This is the temperature graph from SA with all 6 AIO's at idle, turned on at about 6:30am without active cooling. At about 8:15am I've turned on the mini split.

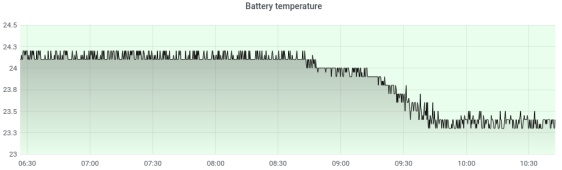

As a side effect, the batteries which are located under the AIO's are also get's a bit cooled because not all of the cold air is sucked in by the AIO's and fall down on top of the batteries (for unknown reasons, 2 of theAIO's will always be about 10°C hotter than the other 4 - this was right from the beginning but they working without any problems... it doesn't matter if they are just idling or under inverter and/or charger load).

--------------

--------------

The 9,000BTU concealed ducted indoor unit is more than enough to cool the system down and it's very energy efficient (about 700W). When I have an ambient of 20°C in the garage, I measure between 5-8°C on the AIO cold air inlets. Looking forward how it will behave when we will have 120 Fahrenheit here in the desert in the next summer with full working MPPT chargers...

This is the temperature graph from SA with all 6 AIO's at idle, turned on at about 6:30am without active cooling. At about 8:15am I've turned on the mini split.

As a side effect, the batteries which are located under the AIO's are also get's a bit cooled because not all of the cold air is sucked in by the AIO's and fall down on top of the batteries (for unknown reasons, 2 of theAIO's will always be about 10°C hotter than the other 4 - this was right from the beginning but they working without any problems... it doesn't matter if they are just idling or under inverter and/or charger load).

Last edited: