robbob2112

Doing more research, mosty harmless

Just putting this thread together as a place for me to post answers to common questions I see over and over.

Whatever you read below is my opinion - read at your own risk -

I found them all in the cellar at the end of the hall in the bottom of a locked filing cabinet stuck in a disused lavatory with a sign on the door saying 'Beware of the leopard.'

If you are new and reading this and have question - please post a new thread.

If you are more experinced and have a correction or disagree with what I have here - post and I'll make the correction if it makes sense.

#1 - how to decide battery voltage and also figure how many panels you need.

diysolarforum.com

diysolarforum.com

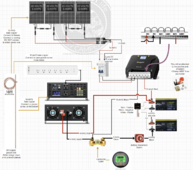

#2 - Sample system - off grid cabin - 24v - 4 panels - bougerv mppt -

diysolarforum.com

diysolarforum.com

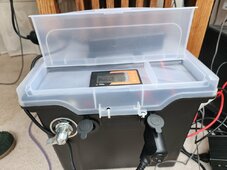

#3 - My CPAP backup unit

diysolarforum.com

diysolarforum.com

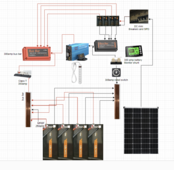

#4 - Sample system - 4 x 12v parallel off grid - don't use

diysolarforum.com

diysolarforum.com

#5 - Tools - Things I have and use - YMMV

diysolarforum.com

diysolarforum.com

#6 - Ferrule usage

diysolarforum.com

diysolarforum.com

#7 - Do you need an equalizer/active balancer with series strings of batteries

Running strings of 2 and 4 batteries - do you need an equalizer - it depends - if you charge discharge the same amount day after day you need an equalizer - if you run totally random patterns that are from 20 to 80% usage every day you don't. BUT, very few actually run a totally random pattern day after day. The sun rises and sets, the ac cycles on and off, etc. So random in the day will delay the batteries but they will get out of sync and require being put in parallel or disassembly and charging individually.

diysolarforum.com

diysolarforum.com

diysolarforum.com

diysolarforum.com

#8 - How to choose system voltage

diysolarforum.com

diysolarforum.com

#9 - What are common types or wire and usage

diysolarforum.com

diysolarforum.com

#10 - Buried conduit - NEC and rules

diysolarforum.com

diysolarforum.com

#11 - Wires on a rooftop

diysolarforum.com

diysolarforum.com

#12 - Fuses, disconnects/isolators, and breakers on PV lines

diysolarforum.com

diysolarforum.com

Good links to read not by me

Hooking multiple batteries in parallel and where on the bus bar to place the uplink cables.

diysolarforum.com

diysolarforum.com

Gasses released by LiFePO4 batteries during a cell vent. I have this one as a PDF, but it is to large to post -- just in case it disappears

www.ncbi.nlm.nih.gov

www.ncbi.nlm.nih.gov

Probably the neatest DIY Battery rack I have ever seen

diysolarforum.com

diysolarforum.com

Running strings of 2 and 4 batteries - do you need an equalizer - it depends - if you charge discharge the same amount day after day you need an equalizer - if you run totally random patterns that are from 20 to 80% usage every day you don't.

diysolarforum.com

diysolarforum.com

diysolarforum.com

diysolarforum.com

Rules to live by -

#1 - there can be only one - this is when talking about grounding - one rod - one grounding system - one ground potential for all equipment

#2 - never stack lugs - You can get away with a lug and a ring terminal on top, but never stack larger lugs

#4 - You can do it right, or you can do it over once it burns down

#5 - buy cheap, buy twice, or three times depending on how long it takes you to learn

#6 - Fuse EVERY live wire

#7 - Use the right type and amperage of fuse

#8 - Class T fuses are expensive but if sized right they only blow when they save your butt.

#9 - If it seems to good to be true, it is

#10 - Buy the voltage battery you need, don't try and string them together for higher, it causes problems

#11 - Trying to reuse your old equipment in your new design will cost you in the end - money or efficiency

#12 - if you didn't listen to #10 & #11 use an active equalizer/balancer to keep them in balance.

Last one - Everyone has an opinion - the hard part is deciding which one is worth listening to

External links I want to remember -

Raw copper bus bar material

www.mcmaster.com

www.mcmaster.com

Custom bent/cut/punched/plated busbar assemblies

www.conexcopper.com

www.conexcopper.com

No-OX-id Special A grease - use it on all contact surfaces

www.sanchem.com

www.sanchem.com

EM radiation song

diysolarforum.com

diysolarforum.com

Whatever you read below is my opinion - read at your own risk -

I found them all in the cellar at the end of the hall in the bottom of a locked filing cabinet stuck in a disused lavatory with a sign on the door saying 'Beware of the leopard.'

If you are new and reading this and have question - please post a new thread.

If you are more experinced and have a correction or disagree with what I have here - post and I'll make the correction if it makes sense.

#1 - how to decide battery voltage and also figure how many panels you need.

Robbob2112 Answer thread

Just putting this thread together as a place for me to post answers to common questions I see over and over. Whatever you read below is my opinion - read at your own risk - I found them all in the cellar at the end of the hall in the bottom of a locked filing cabinet stuck in a disused...

#2 - Sample system - off grid cabin - 24v - 4 panels - bougerv mppt -

Robbob2112 Answer thread

Just putting this thread together as a place for me to post answers to common questions I see over and over. Whatever you read below is my opinion - read at your own risk - I found them all in the cellar at the end of the hall in the bottom of a locked filing cabinet stuck in a disused...

#3 - My CPAP backup unit

Robbob2112 Answer thread

Just putting this thread together as a place for me to post answers to common questions I see over and over. Whatever you read below is my opinion - read at your own risk - I found them all in the cellar at the end of the hall in the bottom of a locked filing cabinet stuck in a disused...

#4 - Sample system - 4 x 12v parallel off grid - don't use

Robbob2112 Answer thread

Just putting this thread together as a place for me to post answers to common questions I see over and over. Whatever you read below is my opinion - read at your own risk - I found them all in the cellar at the end of the hall in the bottom of a locked filing cabinet stuck in a disused...

#5 - Tools - Things I have and use - YMMV

Robbob2112 Answer thread

Just putting this thread together as a place for me to post answers to common questions I see over and over. Whatever you read below is my opinion - read at your own risk - I found them all in the cellar at the end of the hall in the bottom of a locked filing cabinet stuck in a disused...

#6 - Ferrule usage

Robbob2112 Answer thread

Just putting this thread together as a place for me to post answers to common questions I see over and over. Whatever you read below is my opinion - read at your own risk - I found them all in the cellar at the end of the hall in the bottom of a locked filing cabinet stuck in a disused...

#7 - Do you need an equalizer/active balancer with series strings of batteries

Running strings of 2 and 4 batteries - do you need an equalizer - it depends - if you charge discharge the same amount day after day you need an equalizer - if you run totally random patterns that are from 20 to 80% usage every day you don't. BUT, very few actually run a totally random pattern day after day. The sun rises and sets, the ac cycles on and off, etc. So random in the day will delay the batteries but they will get out of sync and require being put in parallel or disassembly and charging individually.

Do I need an Active balancer for two 12.8v 100ah in series?

Easy to add later if an issue develops. Not a permanent skip feature on a large component.

Do I need an Active balancer for two 12.8v 100ah in series?

Easy to add later if an issue develops. Not a permanent skip feature on a large component.

#8 - How to choose system voltage

Robbob2112 Answer thread

Just putting this thread together as a place for me to post answers to common questions I see over and over. Whatever you read below is my opinion - read at your own risk - I found them all in the cellar at the end of the hall in the bottom of a locked filing cabinet stuck in a disused...

#9 - What are common types or wire and usage

Robbob2112 Answer thread

Just putting this thread together as a place for me to post answers to common questions I see over and over. Whatever you read below is my opinion - read at your own risk - I found them all in the cellar at the end of the hall in the bottom of a locked filing cabinet stuck in a disused...

#10 - Buried conduit - NEC and rules

Robbob2112 Answer thread

Just putting this thread together as a place for me to post answers to common questions I see over and over. Whatever you read below is my opinion - read at your own risk - I found them all in the cellar at the end of the hall in the bottom of a locked filing cabinet stuck in a disused...

#11 - Wires on a rooftop

Robbob2112 Answer thread

Just putting this thread together as a place for me to post answers to common questions I see over and over. Whatever you read below is my opinion - read at your own risk - I found them all in the cellar at the end of the hall in the bottom of a locked filing cabinet stuck in a disused...

#12 - Fuses, disconnects/isolators, and breakers on PV lines

Robbob2112 Answer thread

Fuses, DIsconnects, and breakers on PV lines Under the 2023 National Electrical Code (NEC), specific requirements exist for the installation and use of photovoltaic (PV) system components such as isolators, fuses, and circuit breakers. Here's a detailed explanation: ### PV Isolator...

Good links to read not by me

Hooking multiple batteries in parallel and where on the bus bar to place the uplink cables.

Calculation of parallel string battery currents

Hi, everybody! I'm a retired EE. I didn't want my EE skills to fade away after retirment, so I exercise them when I can. Whenever I see a non-trivial circuit analysis problem on one of various forums I frequent, I challenge myself to solve it. Recently I watched Will's video about current...

Gasses released by LiFePO4 batteries during a cell vent. I have this one as a PDF, but it is to large to post -- just in case it disappears

Simulation of Dispersion and Explosion Characteristics of LiFePO4 Lithium-Ion Battery Thermal Runaway Gases

In recent years, as the installed scale of battery energy storage systems (BESS) continues to expand, energy storage system safety incidents have been a fast-growing trend, sparking widespread concern from all walks of life. During the thermal runaway ...

Probably the neatest DIY Battery rack I have ever seen

This is my first Diy battery rack. Any advice on how to improve it or important things i may have missed?

Hawkeye experts dont crucify me too harshly

Running strings of 2 and 4 batteries - do you need an equalizer - it depends - if you charge discharge the same amount day after day you need an equalizer - if you run totally random patterns that are from 20 to 80% usage every day you don't.

Do I need an Active balancer for two 12.8v 100ah in series?

Easy to add later if an issue develops. Not a permanent skip feature on a large component.

Do I need an Active balancer for two 12.8v 100ah in series?

Easy to add later if an issue develops. Not a permanent skip feature on a large component.

Rules to live by -

#1 - there can be only one - this is when talking about grounding - one rod - one grounding system - one ground potential for all equipment

#2 - never stack lugs - You can get away with a lug and a ring terminal on top, but never stack larger lugs

#4 - You can do it right, or you can do it over once it burns down

#5 - buy cheap, buy twice, or three times depending on how long it takes you to learn

#6 - Fuse EVERY live wire

#7 - Use the right type and amperage of fuse

#8 - Class T fuses are expensive but if sized right they only blow when they save your butt.

#9 - If it seems to good to be true, it is

#10 - Buy the voltage battery you need, don't try and string them together for higher, it causes problems

#11 - Trying to reuse your old equipment in your new design will cost you in the end - money or efficiency

#12 - if you didn't listen to #10 & #11 use an active equalizer/balancer to keep them in balance.

Last one - Everyone has an opinion - the hard part is deciding which one is worth listening to

External links I want to remember -

Raw copper bus bar material

McMaster-Carr

McMaster-Carr is the complete source for your plant with over 595,000 products. 98% of products ordered ship from stock and deliver same or next day.

Custom bent/cut/punched/plated busbar assemblies

Custom Copper Busbar Assemblies | Conex Copper Busbar

Manufacturers of Custom Copper Busbar Assemblies, Exporters of Custom Copper Busbar Assemblies, Suppliers of Custom Copper Busbar Assemblies, Fabricated

No-OX-id Special A grease - use it on all contact surfaces

NO-OX-ID Electrical Contact Grease- Conductive Lubricant | Sanchem, Inc.

NO-OX-ID electrical contact grease prevents the formation of corrosion deposits & keeps metals free from rust & corrosion. Buy electrical conductive lubricant now!

EM radiation song

Robbob2112 Answer thread

Just putting this thread together as a place for me to post answers to common questions I see over and over. Whatever you read below is my opinion - read at your own risk - I found them all in the cellar at the end of the hall in the bottom of a locked filing cabinet stuck in a disused...

Last edited: