Hedges

I See Electromagnetic Fields!

- Joined

- Mar 28, 2020

- Messages

- 20,912

Anything else I should do? Thoughts? Also, thanks everybody for your help!

Can you apply a test load (rather than driving the mower)?

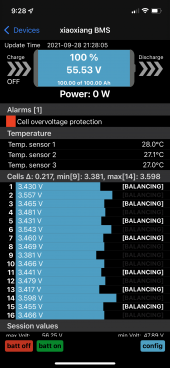

Check BMS reported cell voltages under load. Check with DMM.

Ideally, check voltage from one cell terminal to the next which is shorted to it by busbar. That way DMM reads near zero volts for more digits resolution, rather than near 3.5V, but probably not accessible.

After a heavy load (e.g. test load for a period of time, or after a vigorous mowing run, check temperature of each busbar. Any hotter than others would mean poor contact.

One other question I have... Since I don't need anywhere near the capacity. Do you think I should change the max charge to something less than 100% to maximize battery life? I know this is the case with my car which uses Lithium Ion. Is LiFePo4 similar with max charge and longevity?

Typically LiFePO4 cells are balanced once up to 3.65V and some tail current, then charged each time to a lower voltage like 3.5V.

Lower voltage for storage would be less degradation. Holding at higher voltage allow cells to diverge enough to balance.

If your mowing session uses 50% +/- of capacity, I'd think that would be a good SoC for storage. Then recharge shortly before next use.

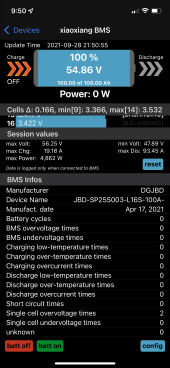

You didn't report on top balance experience. To what voltage do you charge? How far apart were the cells at that max voltage?

Goal is to have charge/discharge always stop without reaching limits where BMS disconnects (for either pack voltage or cell voltage & voltage differences)