AgroVenturesPeru

New Member

- Joined

- Sep 19, 2020

- Messages

- 411

This is international, and US codes don't apply, but that said, all the youtube videos from the USA say that you can't have your PV cables touching the roof. Why not? Is the roof going to heat up to the point to fry them? How would you keep them from touching the roof? It sounds like a tall order in my situation.

I've done an internet search and looked at youtube videos, but haven't found anything that addresses my particular situation.

I am going to put sixteen PV modules on the roof of the house we're building. 4s4p. I've got some roof mount structures to put them on.

It's a corrugated metal roof (see photos), and local builders recommend placing boards on this kind of roof instead of walking directly on the roof. So, already it sounds like the install is going to be time consuming, having to constantly move boards around when needing to move from point A to point B on the roof.

It's a corrugated metal roof (see photos), and local builders recommend placing boards on this kind of roof instead of walking directly on the roof. So, already it sounds like the install is going to be time consuming, having to constantly move boards around when needing to move from point A to point B on the roof.

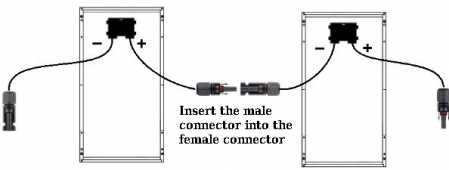

The PV modules, like most, have their positive and negative MC4 connection on the underside. I have plenty of MC4 connectors in a separate bag, and am also equipped with a 100 meter roll of PV red cable and a 100 meter roll of PV black cable. I'm going to have to cut & strip the cables and crimp on the MC4 connectors myself, which I have the tools to do all that. However, I'm just not sure I should work on all that up on the roof. Also the VOC rating is 49V, so it would be a bit dangerous to connect wires to a live panel. Although the MC4 connectors are meant to protect you from touching bare wire, right?

Do you recommend doing a general calculation of the length of each piece of cable ahead of time; and then cut, strip and crimp a male or female MC4 before getting on the roof? If I were to do it this way, I'd have to add a little slack to each length of cable and triple check that my calculation is correct god forbid I don't cut a long enough section of wire.

I've yet to see a single video of someone unrolling a spool of cable on the roof and connecting it to the undersides of the panels and then wiring the home run. Most tutorials online show optimizers and pre-wired Mine's an off-grid system, and the spacing is rather unconventional.

I've done an internet search and looked at youtube videos, but haven't found anything that addresses my particular situation.

I am going to put sixteen PV modules on the roof of the house we're building. 4s4p. I've got some roof mount structures to put them on.

It's a corrugated metal roof (see photos), and local builders recommend placing boards on this kind of roof instead of walking directly on the roof. So, already it sounds like the install is going to be time consuming, having to constantly move boards around when needing to move from point A to point B on the roof.

It's a corrugated metal roof (see photos), and local builders recommend placing boards on this kind of roof instead of walking directly on the roof. So, already it sounds like the install is going to be time consuming, having to constantly move boards around when needing to move from point A to point B on the roof.The PV modules, like most, have their positive and negative MC4 connection on the underside. I have plenty of MC4 connectors in a separate bag, and am also equipped with a 100 meter roll of PV red cable and a 100 meter roll of PV black cable. I'm going to have to cut & strip the cables and crimp on the MC4 connectors myself, which I have the tools to do all that. However, I'm just not sure I should work on all that up on the roof. Also the VOC rating is 49V, so it would be a bit dangerous to connect wires to a live panel. Although the MC4 connectors are meant to protect you from touching bare wire, right?

Do you recommend doing a general calculation of the length of each piece of cable ahead of time; and then cut, strip and crimp a male or female MC4 before getting on the roof? If I were to do it this way, I'd have to add a little slack to each length of cable and triple check that my calculation is correct god forbid I don't cut a long enough section of wire.

I've yet to see a single video of someone unrolling a spool of cable on the roof and connecting it to the undersides of the panels and then wiring the home run. Most tutorials online show optimizers and pre-wired Mine's an off-grid system, and the spacing is rather unconventional.

Last edited: