OffGridForGood

Catch, make or grow everything you can.

The net energy will be the scale to evaluate: if an energy storage system needs to use a portion of that stored energy for temperature regulation with Lithium, but does not need temperature regulation with Sodium - this will be a huge impact.There seems to be some relatively serious investment going into sodium batteries.

At this point, it looks more feasible for large energy storage projects, though the 5000 cycle is considerably less than Lithium provides so it seems like there would have to be a very substantial cost offset.

Time will tell.

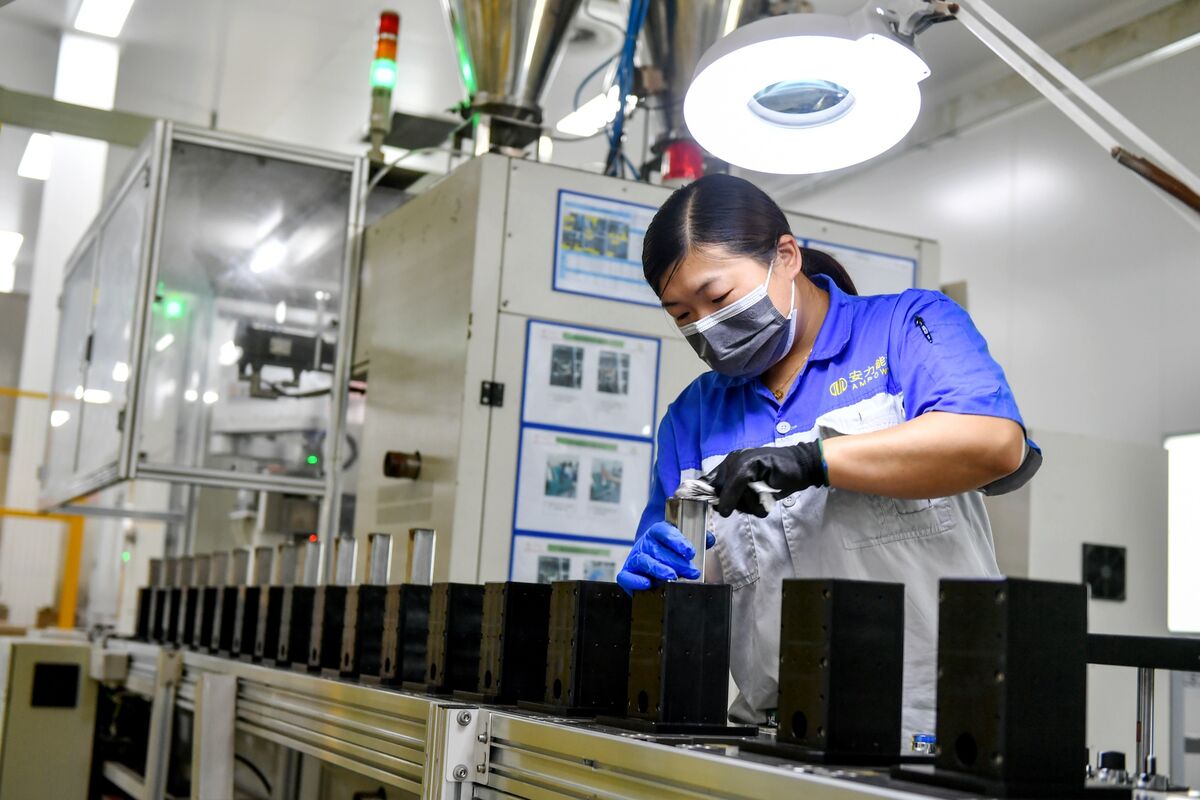

Sodium in Batteries: Shift May Herald Another Shakeup

Battery giants are starting to put their money on new sodium-based technology, a sign that there could be yet another shakeup in the industry that’s crucial for the energy transition.www.bloomberg.com

Imagine the energy use for A/C just to keep batteries cool in hot locations (like TX, AZ, NM, So-Cal), or likewise the energy to maintain at least 32F temps in colder climates (AK, Canada, Finland, etc) - a cell that needs no heating or cooling is a big win.

All that said, the Sodium cells have a much wider voltage curve and to use them with existing inverters, I expect we will not use the full voltage range. This will be a pos and neg thing" pos - the cells will last a long time being cycled through a smaller voltage range than their capacity; neg - the availabel usable capacity will be lower. I am excited to get some to try out.