I was wondering if any one has had a solar panel fail by shorting to the aluminum frame where the frame and glass meet. If so is there anything I can do to prevent this? My oldest panels are 10 years old. The rest are under that. They are Sanyo brand panels. Just wondering if this is what I can expect from the other 60 of my Sanyo panels. Thanks in advance

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Solar panel failure

- Thread starter Ietech

- Start date

Solar Guppy

Red Cobra Guppy

I would be suspect of how they are mounted and something has caused a short. Most panels have clearances to the frame as well as glass and tedlar, so first step is to understand what is the exact cause and work from there.

For example, what is the mounting hardware, bolt or screws to the frame? and if so are they puncturing the tedlar?

For example, what is the mounting hardware, bolt or screws to the frame? and if so are they puncturing the tedlar?

They are not failing anywhere near where they are mounted. It is always on the lower end of the panel and seems the sealing material is letting moisture in. Was just wondering if anyone has tried to reseal the edges with any kind of material. I realize the shortage ones are history. Just trying to extend the life of the rest of them so I don’t have to replace them all at once.

Texas-Mark

Solar Addict

- Joined

- Aug 4, 2021

- Messages

- 1,287

I realize the shortage ones are history.

I would not toss them yet until I knew what the issue was and if it was correctable. Even then, I would find a use for them as long as they are outputting.

Solar Guppy

Red Cobra Guppy

You need to root cause the failure, then can make a plan to address. I've never read on forums any large scale issue with Sanyo Solar panels.

What is the exact symptoms you are seeing? How did you determine there is a short?

Rain water doesn't seem like it would do much of anything and isn't a low resistance path for electricity.

What is the exact symptoms you are seeing? How did you determine there is a short?

Rain water doesn't seem like it would do much of anything and isn't a low resistance path for electricity.

chrisski

Solar Boondocker

- Joined

- Aug 14, 2020

- Messages

- 5,226

For me there's a bit more that goes into the wiring and how many to put in series. I'll show you the way I calculated my using This voltage loss calculator. The thickness, weight and cost of the wire from the combiner to the SCC made me not use the 6P configuration.I also am wondering what configuration of any panel is more efficient, higher voltage and less amps or max amperage and less voltage. I realize the wattage will figure up either way. Just wondering about the efficiency

My calculations are very conservative, and some will find the wire size I end up with way too thick. I am happy with the results.

====================================================

For my six - 100 panel string on my RV build that always deals with shade, the most efficient way is as many in parallel as possible, until wire thickness gets too much for voltage loss, too heavy to put up, or too much of a loss. Another thing is the max wire gauge accepted by the SCC.

I decided I wanted a 3% total loss from panel to SCC. You could probably go higher. There were two legs: The first Panel to combiner, and then Combiner to SCC.

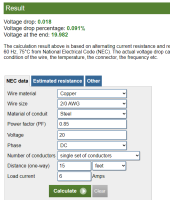

Panels accept up to 10 AWG cables for MC4, so loss on the panel to combiner leg is 10 AWG. With 20 volts, 6 amps, and 15 feet, the loss came out to 1.5%:

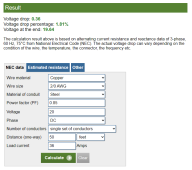

Now for the combiner to Battery portion, the voltage is still 20 volts, the amperage combines to 36 amps, and the distance is 50 feet. So, ampacity becomes an issue, and I want a minimum of 8 AWG wire for ampacity. Voltage loss will drive a higer than 8 AWG wire to meet a 1.5% loss, which comes out to 2/0. This is about $3.80 per foot.

===============================

You can also change the math around so that you accept more than a 3% loss, maybe 10% and the wires get thinner. Honestly, a 10% loss in production could equate to a charging time of 5 and a half hours with a 10% loss compared to 5 hours for a 3% loss.

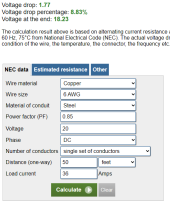

a 10% total loss would be 10 AWG from panels to Combiner, and then 6 AWG from combiner to Battery:

============================

You could also choose to combine closer to the SCC and that would make the high amperage run shorter, or even work to get the SCC much closer to the batteries. Also, if you ever plan on going to 24 volts, you need to at least put the panels 2S to get enough voltage for the SCC to charge those.

===============================

Attachments

solarpanel01

New Member

Along with all this, you can also choose the service services of GosolarGoGreen, along with the maintenance of your solar, it gives you other services, which can prove to be very beneficial for your solar panel.

Similar threads

- Replies

- 14

- Views

- 394

- Replies

- 13

- Views

- 754