kipper

New Member

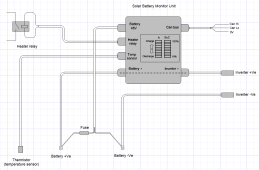

OK, I'm about to order a Solis S5-EH1P-L 3KW hybrid inverter and batteries to replace my now defunct Sunny boy.

As for the battery I'm going to struggle to drag a 40Kg pylontech / Fogstar rack mount battery up into the loft and mount it to the inside of the gable end, however, I do like the idea of constructing my own LifePO4 pack as I've built several successful 10S5P Li-on E-bike battery packs as well as a LIfePo4 portable e-bike charger so have a good handle on what's required, this will mount very neatly to the wall.

Here is what I'm planning;

16 off EVE LF105 3.2V 105Ah prismatic cells in series giving 51.2V / 5KWh

JBD-SP25S003-L16S-100A BMS

Custom steel fire proof thermostatically heated box using silicone heater mats ( these work well on ebike batteries).

Existing PV array;

Pmax 1545W

Voc 273V

Vpm 227V

Ipm 5.13A

The inverter spec seems to be OK with the PV array.

I believe I need to set the inverter to lead acid as this is a dumb battery, for the charge Voltage I'm thinking 56V however I need to make sure this is below the over charge limit of the BMS or it will trigger an inverter fault if the BMS intervenes.

It looks like there is no way of setting an over discharge limit with a dumb battery (which is a bit surprising) so I'm looking at building a Can Bus / Arduino interface and use the Pylontech protocol although I haven't looked into this in detail yet, if I can get the basic system up and running I can add this at a later date.

Any thoughts welcomed.

As for the battery I'm going to struggle to drag a 40Kg pylontech / Fogstar rack mount battery up into the loft and mount it to the inside of the gable end, however, I do like the idea of constructing my own LifePO4 pack as I've built several successful 10S5P Li-on E-bike battery packs as well as a LIfePo4 portable e-bike charger so have a good handle on what's required, this will mount very neatly to the wall.

Here is what I'm planning;

16 off EVE LF105 3.2V 105Ah prismatic cells in series giving 51.2V / 5KWh

JBD-SP25S003-L16S-100A BMS

Custom steel fire proof thermostatically heated box using silicone heater mats ( these work well on ebike batteries).

Existing PV array;

Pmax 1545W

Voc 273V

Vpm 227V

Ipm 5.13A

The inverter spec seems to be OK with the PV array.

I believe I need to set the inverter to lead acid as this is a dumb battery, for the charge Voltage I'm thinking 56V however I need to make sure this is below the over charge limit of the BMS or it will trigger an inverter fault if the BMS intervenes.

It looks like there is no way of setting an over discharge limit with a dumb battery (which is a bit surprising) so I'm looking at building a Can Bus / Arduino interface and use the Pylontech protocol although I haven't looked into this in detail yet, if I can get the basic system up and running I can add this at a later date.

Any thoughts welcomed.