dougbert

Solar Addict

I have no qualms about making neutral a loop, or ground a loop, so long as it doesn't offer a lower resistance path with insufficient ampacity.

When current flows through L, I expect it to return through the closest N (or G in case of a fault), because that offers lowest inductive impedance. (although I haven't checked the math to confirm it does do that at 60 Hz.)

my generator circuit ties into the inverter in the PDP, with Neutral and Ground.

Then I have a L14-30R off of that same circuit

That L14-30R has a GFCI breaker for it as it is located in basement, a wet location per NEC

The CLP uses the same Neutral/Ground tree layout, but without a loop

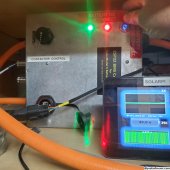

When I plug the adapter cable into the genny L14-30R and then into the CLP, it connects both the Neutral and the ground lines and forms the loops. As that happens the GFCI trips as current is now flowing via both paths - not good.

The feature I hoped for, is not critical and not really needed. I thought it would be neat, but not easily fixed. I could put yet another transfer switch or 4 pole disconnect, downstream before the genny circuit enters the inverter's PDP

naw, not worth it