Spanish Flyer

New Member

Good morning to you all..

I have mentioned this on other threads, but still haven´t sorted out my problem.

It is a fact and now I come to learn about it that during these periods, when we have clear skies or even with slight white cloud presence, and the temperatures are still low in early Spring, that the panels can and will overproduce higher current that what is stated on their specs... So if you, like I did, calculate the total number of panels and their size following the figures given by the panel manufacturer, you can find yourself producing moce CC PV voltage than what your inverters can handle and of course they will trip to protect their hardware.

The problem with removing one or more panels amongst other things is that you will miss the extra power you had during the rest of the year, basically in winter.

In my case I have two strings where I have this problem; I have separated them into two identical inverters and as before one inverter with both strings kept tripping, now both inverters trip, so now instead of reducing my problem I have actually doubled it!!

I am now searching for a dedicated PV adjustable String Circuit breaker where you can adjust it to trip just before the inverter does (FYI, when my inverter trips, both its MPPT's fail to deliver and it can take as much as 5 minutes for the inverter to rearm); with the string circuit breaker I would only loose one string and the inverter would not suffer from so many PV CC current overloads.

I have actually found a breaker that might just solve my problem, at least partially because it doesn't rearm and I would have to connect it every time it trips, but at least I'm protecting the inverter and only one string goes, not both...

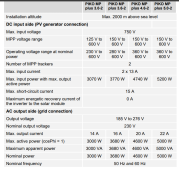

The mentioned breaker is: an EATON PKZ-SOL12 https://www.eibabo.com/en/eaton/dc-string-circuit-breaker-12a-pkz-sol12-eb10782548

Maybe someone has has experience with it.... Pitty though that it doesn't rearm after some time, but I have to sort out my problem ASAP, so if I can't find one that rearms itself, I will go for these...

Best regards

I have mentioned this on other threads, but still haven´t sorted out my problem.

It is a fact and now I come to learn about it that during these periods, when we have clear skies or even with slight white cloud presence, and the temperatures are still low in early Spring, that the panels can and will overproduce higher current that what is stated on their specs... So if you, like I did, calculate the total number of panels and their size following the figures given by the panel manufacturer, you can find yourself producing moce CC PV voltage than what your inverters can handle and of course they will trip to protect their hardware.

The problem with removing one or more panels amongst other things is that you will miss the extra power you had during the rest of the year, basically in winter.

In my case I have two strings where I have this problem; I have separated them into two identical inverters and as before one inverter with both strings kept tripping, now both inverters trip, so now instead of reducing my problem I have actually doubled it!!

I am now searching for a dedicated PV adjustable String Circuit breaker where you can adjust it to trip just before the inverter does (FYI, when my inverter trips, both its MPPT's fail to deliver and it can take as much as 5 minutes for the inverter to rearm); with the string circuit breaker I would only loose one string and the inverter would not suffer from so many PV CC current overloads.

I have actually found a breaker that might just solve my problem, at least partially because it doesn't rearm and I would have to connect it every time it trips, but at least I'm protecting the inverter and only one string goes, not both...

The mentioned breaker is: an EATON PKZ-SOL12 https://www.eibabo.com/en/eaton/dc-string-circuit-breaker-12a-pkz-sol12-eb10782548

Maybe someone has has experience with it.... Pitty though that it doesn't rearm after some time, but I have to sort out my problem ASAP, so if I can't find one that rearms itself, I will go for these...

Best regards