I will do my best to long story short this and give good-ish details. I'm wanting to setup a small array for piping power into my basement to batteries, and eventually probably to an inverter as a backup power solution when power goes out. Located in Kentucky.

So I have about 1,200 watts worth of random solar panels that I've picked up from an auction place over time at about .25 cents per watt. Basically a mixture of 200 watt panels and 100 watt panels, some solid and some flexible.

The plan is to put up 800 watts worth on top of a gazebo type structure that is in my backyard. I plan to use the MPPT that came with one of the auction solar panels I bought, a HQST MC2440N10 (12v/24v, 40 AMP, Mas Voltage of PV 100v, Max Power of PV 550w/12v 1100w/24v). For starting and testing purposes, I got a DJLBERMPW 12V 100Ah LiFePO4 Battery (Amazon Item: B09JNK13YH). Send panels to a combiner box at 24v, then to a MPPT, out to a battery bank for charging, and eventually to a Inverter.

1. First Question: I picked up a Solar Combiner box (Amazon Item: B09WY6VTGT) with 4 inputs and 10 amp fuses with 40 amp total, Max 700w at 12v, 1400W at 24v. I was planning to combine panels to make 24v inputs. So generally combining a 200 watt and 100 watt panel in Series to make 300 watts at 24v. But I'm not sure if the 10 amp fuses on this box are large enough to handle this size of input?

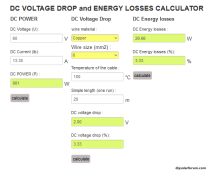

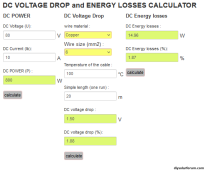

2. Second Question: Once I run power from the solar panels into the combiner box, what gauge wire would I need to run from the combiner box, to the MPPT which will be probably 40-50 ft away?

So I have about 1,200 watts worth of random solar panels that I've picked up from an auction place over time at about .25 cents per watt. Basically a mixture of 200 watt panels and 100 watt panels, some solid and some flexible.

The plan is to put up 800 watts worth on top of a gazebo type structure that is in my backyard. I plan to use the MPPT that came with one of the auction solar panels I bought, a HQST MC2440N10 (12v/24v, 40 AMP, Mas Voltage of PV 100v, Max Power of PV 550w/12v 1100w/24v). For starting and testing purposes, I got a DJLBERMPW 12V 100Ah LiFePO4 Battery (Amazon Item: B09JNK13YH). Send panels to a combiner box at 24v, then to a MPPT, out to a battery bank for charging, and eventually to a Inverter.

1. First Question: I picked up a Solar Combiner box (Amazon Item: B09WY6VTGT) with 4 inputs and 10 amp fuses with 40 amp total, Max 700w at 12v, 1400W at 24v. I was planning to combine panels to make 24v inputs. So generally combining a 200 watt and 100 watt panel in Series to make 300 watts at 24v. But I'm not sure if the 10 amp fuses on this box are large enough to handle this size of input?

2. Second Question: Once I run power from the solar panels into the combiner box, what gauge wire would I need to run from the combiner box, to the MPPT which will be probably 40-50 ft away?