Not the way I'm proposing it isn't, but if you can't access underneath the floor it would complicate things for sure. My issue with air sand is you have to still somehow move the heat around with fans. I have just heard too many people gushing about radiant floor heat and I've liked it the places I've stayed that had it.

I like your style. That 44gal drum is also designed to store water. I'm talking $20 DC water pumps, which are comparable to costs of fans. The thing I like about a diy hydronic system is nothing has to be made for high heat as the water running through the pipes is only around 38C. A bigger tank can store just as much energy as a smaller one at higher temps. Higher temps concern me to some degree.

I do metric, makes sense to me

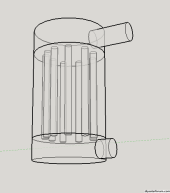

I just got a ton of 40mm x 40mm aluminum extrusion for almost nothing because my fellow Americans don't know what that means and ignored the listing. I actually think Pex is expensive, but I've found people selling unused leftovers for amounts I could afford. One guy was almost giving away 500ft rolls of 10mm plastic tubing, but that is pretty small diameter and probably wouldn't work great so I haven't tried it. Even then, I wouldn't need a single pex connector with my idea. I agree the traditional way of doing hydronic systems is expensive. I haven't quite figured out all the non-pex tubing options that are available. And I'm not totally sold on water just because a single leak could definitely make a disaster whereas hot air would be okay.

I haven't looked at panels of that size since my electronics require 60 cell panels, but I can drive an hour and get used trina 330w panels for $110 before any negotiation. The most interesting thing I've seen lately are new 200w bifacials for $140, which would quality for some tax incentives. It still feels like used panels for $0.20-30/watt is a better deal overall than the tax incentives.

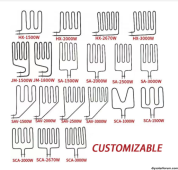

With expensive inverters and electricians... Have you ever seen people who directly hook panels to each other? They put a panel inside their house, disable one of the diodes so energy flows through 40 of the 60 cells, and then connect it to two 60 cell panels outside. For zero electronics cost this puts the panels very near their max power point and you mostly optimize energy production. It isn't a battery of any kind, but the inside solar panel (the mass of glass, aluminum, etc) gets up to 40-50C and heats your house. It doesn't sound perfect, but it also sounds simple and long lasting and automatic. If you do it right it can't get any hotter than panels get on a hot roof in the summer. I'm sure lots of people don't have places to put panels inside their house, it is a little strange... It seems like a decent use of cheap solar panels