Zwy

Emperor Of Solar

Update on the Big Blue Box from over a year ago. https://diysolarforum.com/threads/house-system-battery-box-hoffman.32305/

It's been a long process, I do not have much free time in the summer and this fall the array and EG4's I installed with some additional work done in house. A year ago in March, we cut 12 inches around the outside of the basement floor, jack hammered that out, dug down 18 inches, installed 4 inch tile to the sump pit and clean rock. then cemented it back up shut. Then I parged and waterproofed the walls, epoxied the floor. My basement is nice and dry now.

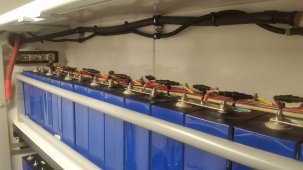

It isn't blue anymore, pics from yesterday and today. Took a little bit to get it into my basement, bolted a section of plywood on the side and slid it down the steps with the legs off. Thanks to my son for helping get it down there in the basement of my old 1905 farmhouse. Basically I put this all together in the shop, then tore it down and painted it. Now it's putting it all back together with the Batrium installed. More to come.

Yesterday

Today

It's been a long process, I do not have much free time in the summer and this fall the array and EG4's I installed with some additional work done in house. A year ago in March, we cut 12 inches around the outside of the basement floor, jack hammered that out, dug down 18 inches, installed 4 inch tile to the sump pit and clean rock. then cemented it back up shut. Then I parged and waterproofed the walls, epoxied the floor. My basement is nice and dry now.

It isn't blue anymore, pics from yesterday and today. Took a little bit to get it into my basement, bolted a section of plywood on the side and slid it down the steps with the legs off. Thanks to my son for helping get it down there in the basement of my old 1905 farmhouse. Basically I put this all together in the shop, then tore it down and painted it. Now it's putting it all back together with the Batrium installed. More to come.

Yesterday

Today