Good Day Arm Chair Electricians

I live in a 2004 Safari Trek 31SBD. It currently has no solar, a 12 battery bank made up of 4 6-volt golf cart batts ( buh bye none too soon) and Freedom 451 Inverter charge controller( also soon to go buh bye). My power needs are vaaaahst :D I run a full size desktop computer and home stereo, recording gear etc etc... and then I intend to add a mini-split... ditching the existing AC and Heat systems. maybe run fridge a hot water on solar... I suck and intend to suck a lot of electrons.

The battery is a 16s 280Ah 48-volt setup using an Overkill 16s 100 amp BMS Cells were US stock from Docan, total $2,469.60. The BMS was approx $170, including longer leads and monitor wires.

The case ... I have been looking at all manner of container solutions for the battery. I have not liked much of what I saw. Plastic boxes were never the right size and all seemed too fragile for the weight I would be putting in them. I then came across a Job Site Tool Box, that was a good fit, and then saw one on Scratch and Dent sale and scooped it up.

Here are the box and battery in a dry fit. I will have to build the battery "in place" when the time comes as the complete unit is 220#s ++ I have lined the bottom and sides with 1/2" closed cell neoprene foam. I will also line the inside of the lid with 1/16" foam where the BMS is not glued to the inside of the lid. I will also place a barrier sheet over the entire battery once built.

Would you consider.... Assemble as is with wax paper in between each cell, or Captan tape them in groups of 2 or 4 and let the tape be the wear points. These are very snug as is, but I can see vibration overtime causing an issue where cells touch. Because of the case build, things get to heavy to maneuver .. 4 groups of 4 taped with 1/8" foam between groups and middle?

I am looking at mounting the box on these....

For an All-In-One I am going with a Sigineer M3048NC

www.sigineer.com

www.sigineer.com

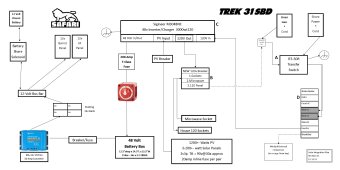

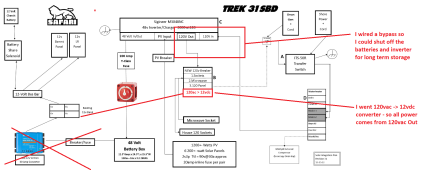

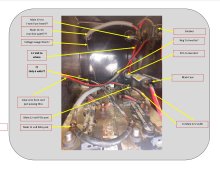

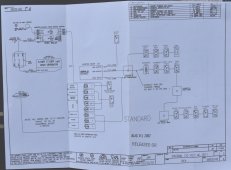

....and for the interesting bit.. .Here is the schematic for the 120v system in the RV as it sits.

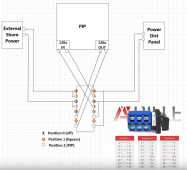

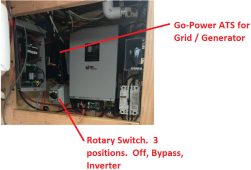

I will be working with a friend who is an electrical engineer in Oct to install all of the above and integrate it with the above existing systems. The 12v is easy, and that feed no longer will be supplying the 120, so I have a Victron 48->12 converter... with 120v load removed from the 12v side, the heaviest draw on the 12v side are the slide motors, so buh-bye massive 12v cables too. For feeding the 120v side, the simplest thing may be to hook up the 120 feed from the Sigineer to the exising feed at the Transfer switch. I do not intend to ever shut the system down as I live in the RV. I am removing the 4kw Onan built in generator, so that feed won't be needed anyway. I also have and plan to keep a small 2.8kw Inverter Generator that had a 30 amp plug that I use currently hooked up to the RV via the external shore power line. The challenge in the above schematic in the EMS system currently in place that sheds loads if they exceed supply.... finding and disabling this system could be a real wild goose chase, let alone iffy in terms of potentially getting that wrong.... so the thought to allow that to think it is still doing its job and leaving it alone...

Why 48volt? Cost and efficiency. If I exceed around 2kw of solar, that is at the top end of the 24v all-in-one units. A 48v all-in-one can go up to 4500+ PV input. I hope to initially get at least 2kw on the roof, but part of that includes deletion of the AC unti and install of the mini-split. (we'll burn that bridge when we get to it. 48 volt also means less $ in copper to move it about ( some of the marine 12v systems of this capacity use gargantuan wires)

Why all-in-one? You add up what a Victron system would cost to manage this setup? The Sigineer unit is $900, and it handles everything.. and yes it is a single point of failure, yet all systems face similar situations of any one component taking down the system. .. risks... versus money... I do.not.have.a.lot.of.money therefore this system is being built as cost effective as I can manage... look at the cost savings on the battery alone, let alone the the comparison between indv components and the all-in-one,,, my choice was and is, built it inexpensive or not at all... and I am taking my time because I am retired and on SS, and I have to... so .. yeah... that said.. I do encourage feedback... I will have fuses and breakers in line and a shunt on the 48v and 12v sides of things.... I have watched hours of Will's videos.. the only downsides to this system are the sheer weight of the battery and the slight risk of 48+ volt shocks... I have prolly neglected to mention something about the build, so do poke away...

I live in a 2004 Safari Trek 31SBD. It currently has no solar, a 12 battery bank made up of 4 6-volt golf cart batts ( buh bye none too soon) and Freedom 451 Inverter charge controller( also soon to go buh bye). My power needs are vaaaahst :D I run a full size desktop computer and home stereo, recording gear etc etc... and then I intend to add a mini-split... ditching the existing AC and Heat systems. maybe run fridge a hot water on solar... I suck and intend to suck a lot of electrons.

The battery is a 16s 280Ah 48-volt setup using an Overkill 16s 100 amp BMS Cells were US stock from Docan, total $2,469.60. The BMS was approx $170, including longer leads and monitor wires.

The case ... I have been looking at all manner of container solutions for the battery. I have not liked much of what I saw. Plastic boxes were never the right size and all seemed too fragile for the weight I would be putting in them. I then came across a Job Site Tool Box, that was a good fit, and then saw one on Scratch and Dent sale and scooped it up.

Here are the box and battery in a dry fit. I will have to build the battery "in place" when the time comes as the complete unit is 220#s ++ I have lined the bottom and sides with 1/2" closed cell neoprene foam. I will also line the inside of the lid with 1/16" foam where the BMS is not glued to the inside of the lid. I will also place a barrier sheet over the entire battery once built.

Would you consider.... Assemble as is with wax paper in between each cell, or Captan tape them in groups of 2 or 4 and let the tape be the wear points. These are very snug as is, but I can see vibration overtime causing an issue where cells touch. Because of the case build, things get to heavy to maneuver .. 4 groups of 4 taped with 1/8" foam between groups and middle?

I am looking at mounting the box on these....

For an All-In-One I am going with a Sigineer M3048NC

3000W Off Grid Stackable PV Inverter 80A MPPT Solar Charger DC 48V to 110V 120V with 40A Utility Charger 50HZ 60HZ

3000W Off Grid High Frequency Stackable Inverter 80A MPPT Solar Charger DC 48V to 110V 120V with 40A Utility Charger 50HZ 60HZ. M3000H-48LV

....and for the interesting bit.. .Here is the schematic for the 120v system in the RV as it sits.

I will be working with a friend who is an electrical engineer in Oct to install all of the above and integrate it with the above existing systems. The 12v is easy, and that feed no longer will be supplying the 120, so I have a Victron 48->12 converter... with 120v load removed from the 12v side, the heaviest draw on the 12v side are the slide motors, so buh-bye massive 12v cables too. For feeding the 120v side, the simplest thing may be to hook up the 120 feed from the Sigineer to the exising feed at the Transfer switch. I do not intend to ever shut the system down as I live in the RV. I am removing the 4kw Onan built in generator, so that feed won't be needed anyway. I also have and plan to keep a small 2.8kw Inverter Generator that had a 30 amp plug that I use currently hooked up to the RV via the external shore power line. The challenge in the above schematic in the EMS system currently in place that sheds loads if they exceed supply.... finding and disabling this system could be a real wild goose chase, let alone iffy in terms of potentially getting that wrong.... so the thought to allow that to think it is still doing its job and leaving it alone...

Why 48volt? Cost and efficiency. If I exceed around 2kw of solar, that is at the top end of the 24v all-in-one units. A 48v all-in-one can go up to 4500+ PV input. I hope to initially get at least 2kw on the roof, but part of that includes deletion of the AC unti and install of the mini-split. (we'll burn that bridge when we get to it. 48 volt also means less $ in copper to move it about ( some of the marine 12v systems of this capacity use gargantuan wires)

Why all-in-one? You add up what a Victron system would cost to manage this setup? The Sigineer unit is $900, and it handles everything.. and yes it is a single point of failure, yet all systems face similar situations of any one component taking down the system. .. risks... versus money... I do.not.have.a.lot.of.money therefore this system is being built as cost effective as I can manage... look at the cost savings on the battery alone, let alone the the comparison between indv components and the all-in-one,,, my choice was and is, built it inexpensive or not at all... and I am taking my time because I am retired and on SS, and I have to... so .. yeah... that said.. I do encourage feedback... I will have fuses and breakers in line and a shunt on the 48v and 12v sides of things.... I have watched hours of Will's videos.. the only downsides to this system are the sheer weight of the battery and the slight risk of 48+ volt shocks... I have prolly neglected to mention something about the build, so do poke away...