Hello everyone

I want to improve my wiring diagram.

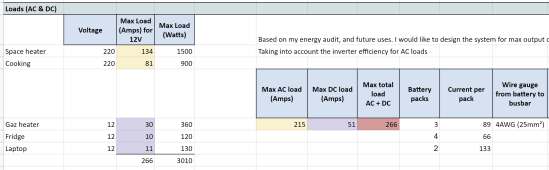

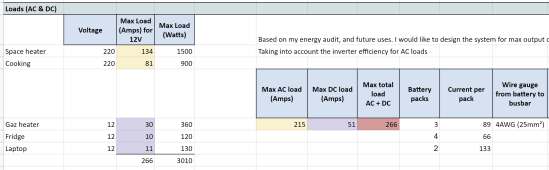

1) Fuse sizing for each battery pack

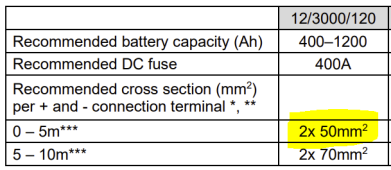

The inverter is a Multiplus 12/3000/120

It's 3000VA, 2400W continous and 5500 peak.

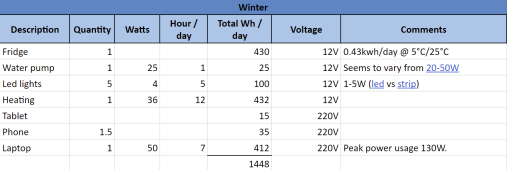

According to my energy audit, max loads and the formulas I found on the forum and guides.

I took into account the inverter effiency for AC loads. 93%

I calculated 266 Amps divided by 3 battery pack. 89A max load per battery pack.

89 * 1.25 head room for the fuse = 111. The one just above is 125Amps.

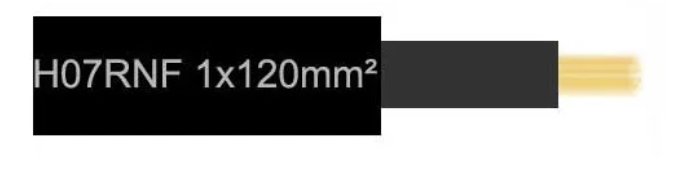

2) Wire sizes for battery positive to fuse

For the wire size to fuse and positive post, I used the bluesea calculator. It suggest 4AWG wires. Up to 155Amps.

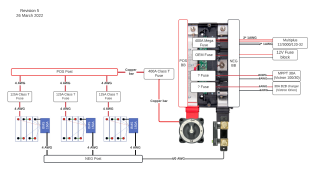

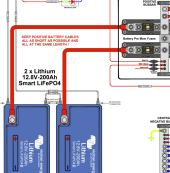

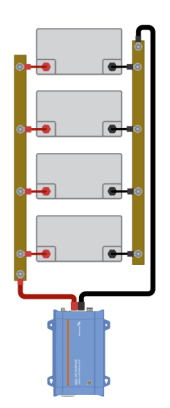

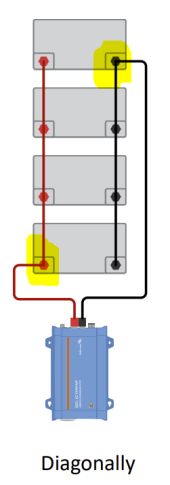

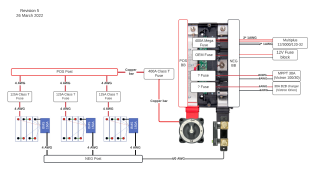

3) Wiring diagram

Any errors you can spot?

I want to improve my wiring diagram.

1) Fuse sizing for each battery pack

The inverter is a Multiplus 12/3000/120

It's 3000VA, 2400W continous and 5500 peak.

According to my energy audit, max loads and the formulas I found on the forum and guides.

I took into account the inverter effiency for AC loads. 93%

I calculated 266 Amps divided by 3 battery pack. 89A max load per battery pack.

89 * 1.25 head room for the fuse = 111. The one just above is 125Amps.

2) Wire sizes for battery positive to fuse

For the wire size to fuse and positive post, I used the bluesea calculator. It suggest 4AWG wires. Up to 155Amps.

3) Wiring diagram

Any errors you can spot?