Bjorn; That's a good point, but lets take that (impractical) idea further; what size fuse would you use? Lets say you have a 100/30, and your panels are a massive array of panels with pairs of my current favourite panel (

430w N-Type TOPCon, with 30 year linear power output warranty ) which has a Voc of 38v (so your Array Voc is 76v - no risk of going over the SCC voltage limit even in the coldest climates) and a panel Isc of 13.84A (Imp = 13.23A). Lets say your array has 500 pairs of these panels, so you have 1000 x 430w = 430,000Wp (or 0.43 MWp - a small solar farm by modern standards even here in New Zealand)

Your array (at STC) can create 500 x 13.84A = 6,920A at Isc, and at max power you could be flowing 6615A.

Your controller (

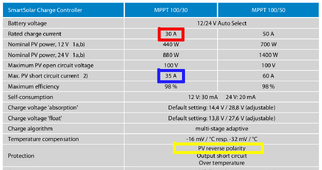

Victron 100/30 ) has these specs;

View attachment 190892

@BjornM - What is your fuse size, and what is the reasoning(s) for this?

I'll start with some issues with this array;

- If part of the array is shaded, you will have a large amount of voltage on the positive cable on one side of the array trying to find the shortest/easiest path to the negative cable, putting stress on the panel diodes on the shaded side? There is no control of the current at the 500-to-one combiner box.

- Even though you have a massive array, its not going to turn moonlight into 30A at the controller - there is a significant hurdle to getting current flowing, so even though in near darkness, with a panel facing *away* from the light source (at least for panels i've tested) you can still get a good voltage (i've seen 30v on a 40v panel), but the slightest attempt to draw power results in zero current.

- We already knew it was a fantasy array, but you've paid about NZD$430,000 (for a while its been an easy formula that panels in NZD are about $1/watt) for an array that produces about 8.6kwh per day, netting you about $2.95, giving you a rough payback period of 454 years. Maybe you need 2 controllers?