bigmanonahill

New Member

- Joined

- Jan 6, 2021

- Messages

- 18

Hello all, I hope this is the right place for this question...

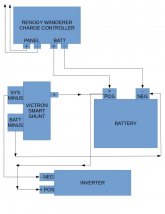

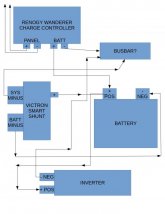

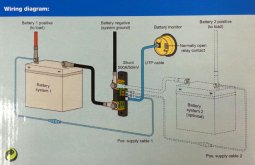

I purchased the Victron Smart Shunt and I'm not entirely certain how to correctly wire the Smart Shunt in this scenario.

I have a 100w Renogy kit with the 30A Wanderer controller, a battery, and an inverter.

I have included a diagram of what I *thought should be correct, however I read this in the Smart Shunt manual;

"there should be no other connections on the battery negative"

If that is the case, then the way it is wired in my diagram is wrong.

Can someone please clearly explain (or even better DRAW a DIAGRAM so my little brain can understand) exactly how to correctly wire this in?

Any help is most appreciated!

I purchased the Victron Smart Shunt and I'm not entirely certain how to correctly wire the Smart Shunt in this scenario.

I have a 100w Renogy kit with the 30A Wanderer controller, a battery, and an inverter.

I have included a diagram of what I *thought should be correct, however I read this in the Smart Shunt manual;

"there should be no other connections on the battery negative"

If that is the case, then the way it is wired in my diagram is wrong.

Can someone please clearly explain (or even better DRAW a DIAGRAM so my little brain can understand) exactly how to correctly wire this in?

Any help is most appreciated!