constantspeed

New Member

- Joined

- Jun 2, 2022

- Messages

- 61

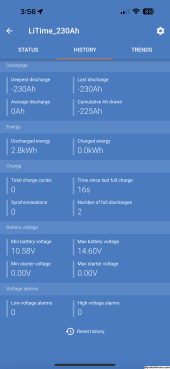

When it comes to battery capacity testing, I see Will using or listing several odd little gizmos for doing so. I see them on Ebay and Amazon. Why can't I simply use my Victron 500A Smart Shunt with the app to run capacity testing on a battery? Fully charge and zero current calibrate to 100%, reset the history, attach a load, and it should, I think, provide an accurate capacity result. Or what am I missing from the equation?