Richard9th

New Member

- Joined

- Apr 25, 2021

- Messages

- 14

I'm setting up a new 50 kWh build for a small camper, and I'm not sure the right voltage to run it at.

I plan to mostly just run everything off of AC via an inverter, rather than using internal DC components.

That makes it pretty easy to buy parts, without having to look for special 12v/24v ones - I can buy regular 110v light bulbs, fridge, inductive cooktop, micro-split, etc.

It looks like I can fit 4 445w solar panels, which look to have an output of vmp of 41, and a voc of 50, and SmartSolar 250 MPPT controller(s).

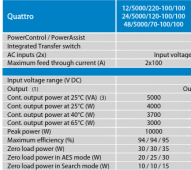

I think I should be able to use those with a Victron Energy Quattro, with one input connected to an inverter from the vehicle alternator/battery, and one input able to be connected to shore power.

I already have a few various 12v lithium batteries from testing, but my understanding is the advice is generally not to mix them, and to do a system with all similar batteries.

Given that I don't have any 12v loads, it seems like 24v would be the default solution?

The efficiency doesn't seem dramatically different either way, and while running thick wires would add a bit of one-time cost, they're relatively short so the cost is pretty small compared to the batteries and other system costs - They're relatively short, so I don't think there would be be all that much efficiency loss.

I suppose 12v seems like it might be *slightly* safer in case of shocks/etc, and potentially easier to buy things that interface with locally. Would a 12v system work better in partial shade? (That part was somewhat confusing to me)

I know I'm relatively inexperienced - What else should I be considering for this build?

I plan to mostly just run everything off of AC via an inverter, rather than using internal DC components.

That makes it pretty easy to buy parts, without having to look for special 12v/24v ones - I can buy regular 110v light bulbs, fridge, inductive cooktop, micro-split, etc.

It looks like I can fit 4 445w solar panels, which look to have an output of vmp of 41, and a voc of 50, and SmartSolar 250 MPPT controller(s).

I think I should be able to use those with a Victron Energy Quattro, with one input connected to an inverter from the vehicle alternator/battery, and one input able to be connected to shore power.

I already have a few various 12v lithium batteries from testing, but my understanding is the advice is generally not to mix them, and to do a system with all similar batteries.

Given that I don't have any 12v loads, it seems like 24v would be the default solution?

The efficiency doesn't seem dramatically different either way, and while running thick wires would add a bit of one-time cost, they're relatively short so the cost is pretty small compared to the batteries and other system costs - They're relatively short, so I don't think there would be be all that much efficiency loss.

I suppose 12v seems like it might be *slightly* safer in case of shocks/etc, and potentially easier to buy things that interface with locally. Would a 12v system work better in partial shade? (That part was somewhat confusing to me)

I know I'm relatively inexperienced - What else should I be considering for this build?

Last edited: