@SunDave What a great flexible plenum to ductwork connection, thank you.

When we redo the ductwork I will ask the installer to add a similar flex connection into the system at the plenum. I think these flex connections both help with vibration suppression and help reduce sound transmission through the ductwork.

Ductboard v Metal v Flexiduct

When redoing our ductwork, I have been debating ductboard over metal. The ductboard will be a preinsulated all-in-one product so there is no need to thermally insulate along the outgoing heat duct and/or the cold return duct if you are being really careful. Certainly it is a cheaper product.

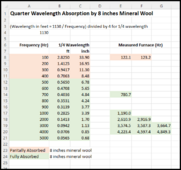

However more importantly to me, the ductboard may better absorb sound but am not 100% sure about this, does anyone have knowledge or experience about this in the forum? Certainly there will not be any metal expansion and contraction sounds with the ductboard.

Reading up on ductwork sound transmission mitigation, people were recommending adding the flexible connection you have at the plenum, plus some curved flexiduct just before the registers & returns, as being a good way of absorbing and stopping sound transmission through the ductwork.

Who knew sound and vibration could be such a challenge? All we want is the quiet sound of air movement but it takes some careful engineering and good installation.