BipedalPrimate

New Member

- Joined

- Mar 25, 2022

- Messages

- 61

Have just received a shipment of 8 LF280K cell from Amy at Luyuan.

Unpacked first box of 2 cells and noticed they show some convexity on long side and concavity on short side.

Interestingly, the convexity on one side not directly opposite convexity on other side.

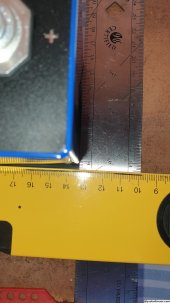

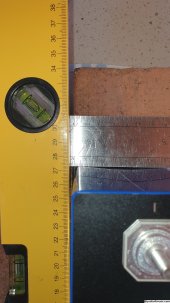

First picture shows top of cell on rest of photos & how distortion was measured.

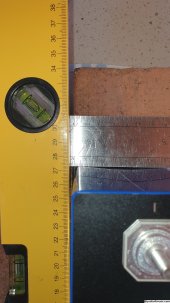

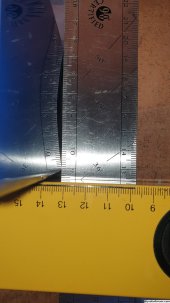

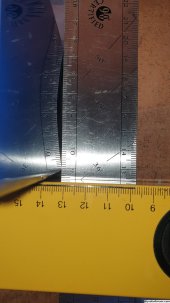

Next pictures are taken from bottom left corner of first picture, moving anti-clockwise to each corner in turn.

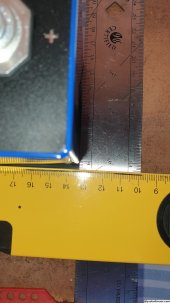

Last picture is short side of positive terminal trying to show concavity.

Objectively, I don't think this an issue but thought I would check with the team that is more experienced than I.

So, two questions:-

Unpacked first box of 2 cells and noticed they show some convexity on long side and concavity on short side.

Interestingly, the convexity on one side not directly opposite convexity on other side.

First picture shows top of cell on rest of photos & how distortion was measured.

Next pictures are taken from bottom left corner of first picture, moving anti-clockwise to each corner in turn.

Last picture is short side of positive terminal trying to show concavity.

Objectively, I don't think this an issue but thought I would check with the team that is more experienced than I.

So, two questions:-

- What is an acceptable level of distortion of newly shipped B Grade cells?

- What method of compression. if any, should be used when combining these cells?

- Manually entering QR code into decoder reveals that they are EVE Power cells, Model Code LF280K (76), Date of Manufacture 22 May 2023.

- Cell Voltage is 3.2888V

- Cell IR is 0.22m Ohms

Last edited: