SilverbackMP

Solar Addict

- Joined

- Apr 4, 2022

- Messages

- 935

I am in the land of mini splits in a very small country surrounded by ocean on three sides. A good chunk of the population is by the ocean given that Seoul-Incheon and Busan are the two biggest cities and both are ports.Hope it works out better than the experience here. https://diysolarforum.com/threads/hot-spot-energy-acdc-solar-mini-split-total-failure.63239/

I don't blame the condenser failures on the manufacturer, it is pretty clear the proximity to the ocean would cause the failures.

Energy usage might be another matter.

I noticing more and more Gree and Midea clones here along with Carrier (Midea). LG (followed by Samsung) is still by far the most numerous, but others are creeping in.

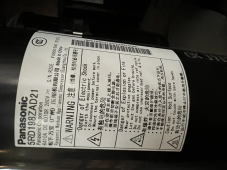

The Toshiba compressors were designed by a company that is native to a chain of islands.

I guess my point is, they should be able to withstand it but apparently can’t.

Last edited: