You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Calculating AIC for fuse selection.

- Thread starter FilterGuy

- Start date

Bob B

Emperor Of Solar

- Joined

- Sep 21, 2019

- Messages

- 8,712

Well .... I'm outdated already after about 3 years out of the workforce. I had arc flash safety training more than once and don't remember anything about AIC. I think the point of the short on our system has the greatest danger of an arc flash.

Guess I have some new stuff to study.

Guess I have some new stuff to study.

Last edited:

An AC breaker can't handle that arc. A DC breaker can. At least that's my understanding.

It takes a lot more voltage for an AC arc and it usually self-extinguishes. The same physical breaker can handle *less* DC voltage (if rated for it at all). DC breakers need special attention to being able to disrupt an arc as well as preserve their contacts. The DC breaker will extinguish the arc (e.g. magnetically) and that's often polarized. Special care needs to be taken with breakers and their ratings -- match their AIC and polarity (if any) to your application.

Last edited:

FilterGuy

Solar Engineering Consultant - EG4 and Consumers

Why is the fault current smaller along the 3 amp circuit?if the 3 amp fuse is protecting a small wire, then a short somewhere along that wire isn't going to be subject to the same available fault current at the battery terminals.

The only explanation for the fault current being smaller is that the circuit resistance is higher. Even when I consider the resistance of smaller wires I can't explain why the fault current would be that much less than at the battery. @smoothJoey's story makes me think the fault current is still pretty high on the smaller fuses.....and I am re-thinking a lot of things I have done for fusing in the past.

FilterGuy

Solar Engineering Consultant - EG4 and Consumers

I may have stepped in it earlier today when my answer to someone with a (somewhat) similar question was that there were two wires, so two fuses. The fuse protects the wire for that segment. If the device cannot be expected to exceed 10 amps, then a 10 amp fuse is appropriate. However, if I'm understanding the "rules" right, we would be looking at no more amps on the wire than 80% of the fuse rating.

In general, you are correct, you don't want to run fuses and breakers at the full breaking current. However, if you use a momentary peak current as the amount for the fuse and the normal runtime is less, you might be OK.

Why is the fault current smaller along the 3 amp circuit?

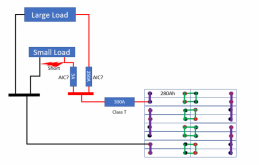

View attachment 39333

The only explanation for the fault current being smaller is that the circuit resistance is higher. Even when I consider the resistance of smaller wires I can't explain why the fault current would be that much less than at the battery. @smoothJoey's story makes me think the fault current is still pretty high on the smaller fuses.....and I am re-thinking a lot of things I have done for fusing in the past.

Only because of the higher resistance, albeit if you short the fuse right at its output, you'll effectively have the same available fault current. Flashing fuses and popping sounds aren't abnormal. In a 48vdc system it might be wise to stick with nothing less than MRBF for branch circuits (it's making me realize I have a simple automotive glass inline 3A fuse protecting my BMS and that might fail spectacularly; I'm only perhaps saved by the fact that it's inline so there's a small wire feeding the fuse, thereby limiting the available current).

@Will Prowse Are you comfortable and willing enough to safely test what happens to various types of fuses under a severe short circuit in a 48v LFP system wired to handle 250 amps? I might but it actually gets a little expensive especially with Class T fuses.

curiouscarbon

Science Penguin

- Joined

- Jun 29, 2020

- Messages

- 3,027

FilterGuy

Solar Engineering Consultant - EG4 and Consumers

I did some real simple modeling. It did not get me very far but here is what I did:

Assumptions

48V Nominal (58.4V peak) 16 cells - 19402 Amps

24V Nominal (29.2V peak) 8 cells - 17697 Amps

12V Nominal ( 14.6V peak) 4 cells - 15052 Amps

If you don't have parallel cells, it is reasonable to say 20KA is the top end of the current. Furthermore, If you add a FET based BMS to the circuit, I would *guess* the total resistance would at *least* double. If it does.... we can assume the max current is around 10KA.

However, if you start putting cells in parallel (e.g. 2PnS or nS2P) the max current goes back up to around 15KA with this model because you have half the per/cell internal resistance.

The short itself is likely to have a reasonable amount of resistance (that is why a lot of heat is generated at the short) I did not try to put in a number for that, but if I did I am sure it would bring the amperage down some.

So..... a slightly informed guess is that for most systems with a FET based BMS, you can assume the max short circuit current would be 15KA or less. A more conservative guess would be 20K or less. Either way..... it is a big number.

I suspect the actual is lower than that... but I don't have the numbers to justify it. That still does not tell me what I should do for that 5Amp fuse I was talking about, but it starts giving us a worst case ballpark for the typical DIY system.

I'll keep trying to flesh this out and put together a better model with better numbers... Maybe I'll do some voltage drop measurements on a loaded system to see what 'actual' resistances are on a real system. If I get anywhere with it I'll post it.

Assumptions

- 280Ah cell internal R - .12 m ohm (Looked up spec)

- Connector resistance per Cell - .05 m ohm (? SWAG ?)

- 300A 50mV shunt - .17 m ohm (50mV/300 = .17)

- Fuse resistance - .12 m ohm (? SWAG - this may be too high by a lot ?)

48V Nominal (58.4V peak) 16 cells - 19402 Amps

24V Nominal (29.2V peak) 8 cells - 17697 Amps

12V Nominal ( 14.6V peak) 4 cells - 15052 Amps

If you don't have parallel cells, it is reasonable to say 20KA is the top end of the current. Furthermore, If you add a FET based BMS to the circuit, I would *guess* the total resistance would at *least* double. If it does.... we can assume the max current is around 10KA.

However, if you start putting cells in parallel (e.g. 2PnS or nS2P) the max current goes back up to around 15KA with this model because you have half the per/cell internal resistance.

The short itself is likely to have a reasonable amount of resistance (that is why a lot of heat is generated at the short) I did not try to put in a number for that, but if I did I am sure it would bring the amperage down some.

So..... a slightly informed guess is that for most systems with a FET based BMS, you can assume the max short circuit current would be 15KA or less. A more conservative guess would be 20K or less. Either way..... it is a big number.

I suspect the actual is lower than that... but I don't have the numbers to justify it. That still does not tell me what I should do for that 5Amp fuse I was talking about, but it starts giving us a worst case ballpark for the typical DIY system.

I'll keep trying to flesh this out and put together a better model with better numbers... Maybe I'll do some voltage drop measurements on a loaded system to see what 'actual' resistances are on a real system. If I get anywhere with it I'll post it.

curiouscarbon

Science Penguin

- Joined

- Jun 29, 2020

- Messages

- 3,027

@FilterGuy the mcmaster carr link from @Hedges was for a 10A fuse with 10,000A interrupt capacity @ 170V. I didn’t look yet but maybe there’s a 5A one?

www.mcmaster.com

www.mcmaster.com

It’s like 5 usd, I personally will be seriously considering this type in the future. Mainly concerned about breakthrough on small branches causing fire hazard.

I’m targeting 8S 100Ah packs. Now I’m fantasizing about a gigavac contactor (2W idle) per pack. T-class fuse on each pack positive. 500A shunt per pack. Want software defined fuse function shunt+contactor too. So much added cost.

McMaster-Carr

McMaster-Carr is the complete source for your plant with over 595,000 products. 98% of products ordered ship from stock and deliver same or next day.

It’s like 5 usd, I personally will be seriously considering this type in the future. Mainly concerned about breakthrough on small branches causing fire hazard.

I’m targeting 8S 100Ah packs. Now I’m fantasizing about a gigavac contactor (2W idle) per pack. T-class fuse on each pack positive. 500A shunt per pack. Want software defined fuse function shunt+contactor too. So much added cost.

Hedges

I See Electromagnetic Fields!

- Joined

- Mar 28, 2020

- Messages

- 20,806

Now I’m fantasizing about a gigavac contactor (2W idle) per pack. T-class fuse on each pack positive. 500A shunt per pack. Want software defined fuse function shunt+contactor too. So much added cost.

Fuse per pack sounds good, sized to handle acceptable imbalance of current or operate with some packs disconnected.

The Gigavac contactors are rated to interrupt 3000A - once.

Those wouldn't make good externally controlled circuit breakers, software or otherwise.

Contactors for such purposes do exist (AC at least) but would have construction to quench arc. I suspect those things cost more than our inverters.

Here are some faster "semiconductor" fuses:

500A, if exposed to 3500A blows in 10 milliseconds. 20,000A available, peak let-through 10,000A; 200,000A available let-through 20,000A

Fuses which are too fast would blow due to surge currents. Would require precharge circuit for inverter caps, and be sized larger than peak load rather than continuous, so larger wires required unless second fuse was required. Some fuses are dual-element to address that.

Those do have higher let-through of fault currents.

500A blows in 10 milliseconds at 6000A, 1 millisecond at 10000A.

Actually as I think about this ... the branch circuits won't be exposed to any more than the upstream fuse rating (at least not for more than the time it takes for the upstream fuse to blow). The available fault current on the branch is equal to the upstream fuse rating, no?

I went ahead and ordered a 3 amp ceramic fuse & holder with 10kA @125VDC rating (from McMaster-Carr) before I realized this. It's probably not necessary but it's designed to blow more safely than a glass fuse and since it's on the plywood at the battery, I'd rather not start a fire with a cheap fuse.

I went ahead and ordered a 3 amp ceramic fuse & holder with 10kA @125VDC rating (from McMaster-Carr) before I realized this. It's probably not necessary but it's designed to blow more safely than a glass fuse and since it's on the plywood at the battery, I'd rather not start a fire with a cheap fuse.

Hedges

I See Electromagnetic Fields!

- Joined

- Mar 28, 2020

- Messages

- 20,806

Actually as I think about this ... the branch circuits won't be exposed to any more than the upstream fuse rating (at least not for more than the time it takes for the upstream fuse to blow). The available fault current on the branch is equal to the upstream fuse rating, no?

I went ahead and ordered a 3 amp ceramic fuse & holder with 10kA @125VDC rating (from McMaster-Carr) before I realized this. It's probably not necessary but it's designed to blow more safely than a glass fuse and since it's on the plywood at the battery, I'd rather not start a fire with a cheap fuse.

For whatever time it takes upstream fuse to blow. Fault current can be quite high, but duration is brief.

The 10kA rated fuses should be good.

One problem would be if they were too fast. I had a fast 30A fuse that came with pile of equipment and used it for either AC into or out of an inverter, can't remember which, but it blew due to inrush with small loads.

Downstream OCP device (e.g. 10A fuse) is exposed to more than upstream device rating (e.g. 500A fuse) because in the event of a short circuit after downstream 10A fuse, the 500A fuse may carry 5000A for 10 milliseconds and the 10A fuse does too.

Two ways for coordinated protection to work. One is the 10A is so slow it doesn't start to blow (or breaker open). It carries 5000A for 10 milliseconds and doesn't get terribly hot before 500A fast fuse completely interrupts the current.

Another is the 10A fuse blows or breaker opens and arcs, but 500A blows fast enough the 10A doesn't explode.

With breakers, you can select coordination so a shorted branch circuit opens the branch breaker and destroys it without shutting down the entire facility. Or, branch circuit delays opening long enough for main facility breaker to open, shutting down the factory but not destroying any breaker.

The fuses I'm seeing can interrupt a 200kA prospective fault so fast that other devices only rated 20 kA don't fail catastrophically. But I'm not finding any which can do that for a 20kA prospective fault from DC battery and protect 2 kA rated components.

Last edited:

FilterGuy

Solar Engineering Consultant - EG4 and Consumers

The interesting thing about this dialog is that there does not seem to be a defined method for figuring this out. (We may be DIYers, but I have found that on this forum, there is usually someone that has at least some of the science behind what is going on and how to do it correctly.)

We have a lot of good information on the properties of DC fuses and DC breakers.... but not much about how to design them into a system. I find this surprising. When it comes to safety devices, there is usually a lot of science and facts available that will guide a design.

The good news is that if this was a big problem.... we would be hearing about it. There are a lot of Marine and RV DC distribution boxes that use tiny automotive fuses and a lot of people installing LiFePO4. If it was a big problem we would be hearing about it. This is not to say we don't need to figure this out and find the best practices.... but it does mean the problem is probably not as big as we could imagine.

We have a lot of good information on the properties of DC fuses and DC breakers.... but not much about how to design them into a system. I find this surprising. When it comes to safety devices, there is usually a lot of science and facts available that will guide a design.

The good news is that if this was a big problem.... we would be hearing about it. There are a lot of Marine and RV DC distribution boxes that use tiny automotive fuses and a lot of people installing LiFePO4. If it was a big problem we would be hearing about it. This is not to say we don't need to figure this out and find the best practices.... but it does mean the problem is probably not as big as we could imagine.

Bri from IA

New Member

- Joined

- Nov 27, 2020

- Messages

- 16

I've wondered about available fault current from large batteries also. Putting together a system right now.

Be careful about fuse data sheets. You'll need to look for specific DC ratings. The time-current curves and peak let-through curves are for AC applications. The AC means the voltage alternates between posative and negative, i.e. with a zero-crossing in the voltage. The zero crossing makes it easier for higher fault currents to be extinquished. No zero-crossings for a DC system, hence when you see fuse ratings, the IR (interupt rating) or AIC (available "I" [current] capacity) for any particular fuse or breaker, the AC rating is much higher than the DC rating.

I had thought a type ANL fuse was going to be good enough, but the interrupt ratings just don't go nearly high enough.

I think probably the class T fuse (fast acting electronis) is likely the best choice for anything above 60A.

Be careful about fuse data sheets. You'll need to look for specific DC ratings. The time-current curves and peak let-through curves are for AC applications. The AC means the voltage alternates between posative and negative, i.e. with a zero-crossing in the voltage. The zero crossing makes it easier for higher fault currents to be extinquished. No zero-crossings for a DC system, hence when you see fuse ratings, the IR (interupt rating) or AIC (available "I" [current] capacity) for any particular fuse or breaker, the AC rating is much higher than the DC rating.

I had thought a type ANL fuse was going to be good enough, but the interrupt ratings just don't go nearly high enough.

I think probably the class T fuse (fast acting electronis) is likely the best choice for anything above 60A.

Hedges

I See Electromagnetic Fields!

- Joined

- Mar 28, 2020

- Messages

- 20,806

Perhaps, but I do see some curves showing clearing of over-current in as little as 1 millisecond. That would have to work same for DC as for AC.

Wonder how that can jibe with having lower AIC ratings for DC than AC?

Maybe if the time/overcurrent curves extended all the way to 200kA, time would go back up to 16 milliseconds and be valid for AC only?

Some fuses (e.g. class T) are 200 kA AIC for AC, 20 kA IC for DC. One I found (Ferraz Shawmut "Amp Trap") is 200kA for AC and 100kA for DC.

Wonder how that can jibe with having lower AIC ratings for DC than AC?

Maybe if the time/overcurrent curves extended all the way to 200kA, time would go back up to 16 milliseconds and be valid for AC only?

Some fuses (e.g. class T) are 200 kA AIC for AC, 20 kA IC for DC. One I found (Ferraz Shawmut "Amp Trap") is 200kA for AC and 100kA for DC.

The interesting thing about this dialog is that there does not seem to be a defined method for figuring this out. (We may be DIYers, but I have found that on this forum, there is usually someone that has at least some of the science behind what is going on and how to do it correctly.)

We have a lot of good information on the properties of DC fuses and DC breakers.... but not much about how to design them into a system. I find this surprising. When it comes to safety devices, there is usually a lot of science and facts available that will guide a design.

The good news is that if this was a big problem.... we would be hearing about it. There are a lot of Marine and RV DC distribution boxes that use tiny automotive fuses and a lot of people installing LiFePO4. If it was a big problem we would be hearing about it. This is not to say we don't need to figure this out and find the best practices.... but it does mean the problem is probably not as big as we could imagine.

I suspect we haven't hit critical mass for the percentages involved in the failure scenarios to be relevant enough that we'd hear about it.

After I listened to professional solar installers in several networking meetings at the end of each day of an Alt-E conference, I was amazed at how little I knew by comparison -- which (because I have soaked up a lot of information here) implies that this information is not making it to these forums. I bet that these installers would have a clear answer to these questions and/or they don't have to answer the question because the vendor (e.g. an integrated UL-listed battery with its own OCP) has figured it out. It would be interesting to see what those batteries and systems are using (the ones listed for home installation).

I wonder what the percentage of grid-tie systems have batteries involved. No batteries means fewer fusing issues, right?

Regarding why we don't see problems, could it be due to the large majority of installations are using battery systems with lower voltages? A 12v arc is a lot less than a 240v arc.

Regarding why we don't see problems, could it be due to the large majority of installations are using battery systems with lower voltages? A 12v arc is a lot less than a 240v arc.

FilterGuy

Solar Engineering Consultant - EG4 and Consumers

It's hard to say. I know the marine community is seeing an acceleration of the movement to LiFePO4. The number of installations are growing rapidly..... but a lot of them are using drop-ins like Battle-Born. I wonder what the fault current is at the battle-born terminals? Is the problem set any different for them?I suspect we haven't hit critical mass for the percentages involved in the failure scenarios to be relevant enough that we'd hear about it.

However, my point remains valid. There have been several posts mentioning blown fuses with no mention of problems with the fuse. If the problem was so bad that there *will* be large arcs and problems, we would have already heard about it. I feel confident that the chance of a problem with the smaller fuses is significantly less than 100%. I am less confident, but I am guessing it is significantly less than 50%. However, that is not a reason to be complacent. Like I said before, we still need to figure this out and find the best practices.

Interesting. My experience has been different. I have rarely found subjects about LiFePO and Solar from other sources that hasn't been covered on the forum to some level. Furthermore, there are profesional installers on the forum so we *do* get input from people that deal with this every day in many different installs.which (because I have soaked up a lot of information here) implies that this information is not making it to these forums.

Similar threads

- Replies

- 8

- Views

- 663

- Replies

- 2

- Views

- 278

- Replies

- 0

- Views

- 289

- Replies

- 1

- Views

- 162