Midnite Beta Tester

Just Testing

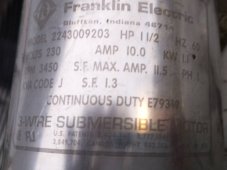

Stopped by Midnite again yesterday, Friday. Only the backside of the booth was disassembled. Inverter display still wired up! OK, lets play a bit. I am told it takes 8-12 hours to assemble the booth. Same for tear down. I did a couple videos of some testing. Applied just over double the Inverters continuous rated load of 6.8kW. I put 14kW on her and then waited to see when the breaker would trip or the inverters protection would shut her down. The 250 amp breaker gave up first. She was pulling 350+ amps for about a minute+. Ignore the AC volts reading on the cheapo Vichy meter. A new battery in it made no difference. Ran test again and my Fluke meter showed a steady 239 VAC.