O/k start from basics.

First build a very strong and rigid hub and bearing assembly that you can do some testing with. You may probably already have that.

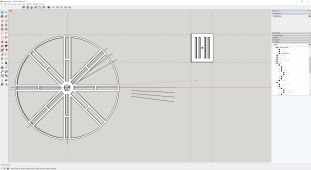

Bolt two thick very strong steel discs onto that, that run perfectly true, and can be adjusted for the distance apart with one or more removable bolted on spacers.

Fit your magnets around the two inside faces of both the steel discs, so they alternate, north pole up/south pole up around the disc edge.

Arrange it, so the north pole on one disc is facing directly towards the south pole on the other opposing disc.

There will then be a massively strong attractive magnetic force between the two discs, which is why the whole thing needs to be built extremely strong.

Start testing with just one coil. The wire you use must be thick enough to carry the expected final current. How many turns will fit depends on the space available in the air gap between the magnets. Fewer turns mean you can reduce the separation between the rotating magnets and still have a safe clearance. That greatly increases magnetic field strength, but few turns also reduces the voltage. Adding more turns means the discs must be set further apart to clear the fatter winding. Do some testing to work out the best compromise combination.

Fewer turns means less total wire length, and a lower ohmic resistance, which will give better voltage regulation. So don't be in too much of a hurry to keep adding turns making huge coils with excessive turns, unless that shows as a definite advantage of voltage versus rpm.

Do all your testing under full load current, one winding will have only a dissapointingly low voltage all by itself, but it still must be able to produce full expected final current.

After a lot of testing and experimentation, you should have something that will run at full final load current continuously without getting too hot, and you will also by then have a pretty good idea of the voltage generated versus rpm for that one single solitary coil.

If you (for example) plan on 1.2Kw at 60 volts, that will be 20 final dc amps. The current in each leg of a three phase alternator should be designed for 83% of that, or be capable of running continuously at sixteen to seventeen amps. The reasons for that are rather complicated, so don't worry about it.

Just realize that whatever ac current your test coil is happy running at, you will get about roughly 20% more dc current than that when there are three phases feeding into a six diode rectifier. Concentrate first in safely reaching the required current without overheating, don't worry about the final voltage at this stage !

How hot the windings get is difficult to estimate, it depends on how well they can shed heat, so practical testing will be the best way to find out.

As its only one coil you are testing, that should not be too difficult.

Once you know your alternator can run at the required full rated current, its then just a case of completing windings for all three phases.

The only question then is how fast it needs to turn to generate 60 volts dc.

Realize that it can generate ANY required voltage, it just needs to turn fast enough.

Output voltage will be directly proportional to rpm.

Until you have built and tested your wind turbine, there is no way of knowing what sort of step up drive ratio you will need to match the two together.

Forget about direct drive and 60rpm, that is never going to work.

Also forget about metal powder, that is not going to work either.

You say you will never use any type of gearing or speed step up.

That is most unfortunate too.

I wish you luck, but a correct methodical engineering approach to all this is the only way its ever going to be successful.

Fully sick is not going to cut it...

Yes sir, You are the first to set me free. Thank you.

I was still torn between small scale tests and full scale tests and opted for leaning as much as I could towards full scale because I have been shouting from rooftops and I did not want to disappoint anyone.

And even that can not get any better than 1/8th of the alternator at a time as I bit off far more than I can swallow.

Sooo many aspects to consider so thank you for real.

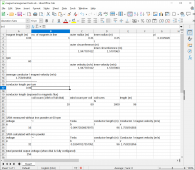

I hope my dear readers can revel in the results thus far in that an 80 wind (160 n (turn) ) without iron powder can do around 1.6V at 60 rpm.

Please allow me to explain why I keep saying wind, in the context of coil winding, while others keep saying turn.

That is because a wind, at least how I use it, is a full rotation of wire how I see it. And a turn is just a 180deg. We'll need 2 turns to have a single wind. If I am screwing up here big time please let me know.??????

And I would not be me if I would not foreshadow something amazing. So here goes. I think I have confirmed that a 10mm iron powder disk is likely to double the voltage output. I did so using 2 tests.

1) using my tesla meter to see the difference. And lo and behold and actuall increase of around 100% tesla.

2) a super botched early run of the actual 1/8th disk that showed 30v (that is an increase of 14 volts over the non iron powder test) but there are soo many things wrong with that test that I did not dare to post it yet.

Now I love the fact that you are trying to help and please never stop doing that. However. Did you miss my post in where I pointed out the things that are to my believe sub optimal with your proposal? Now I am not saying mine is better than the standard. I am only saying I have reason to investigate if my train of thought has any merit.

So I will scale things down for the time being. So sorry crew, no car light funerals just yet ;(

I will take your advice with both arms and going single coil testing for the time being.

It will aid in soo many more things, one of them that it is soo much faster to print new ideas while wasting soo much less material for discarded ideas.

And given this law I pointed at a while back, of which the name eludes me right now. The voltage = flux field strength x coil turns x field reversal freq. one.

It really should not matter at what scale I show Sick® results.

But left or right, thank you for trying to keep my feet on the ground.

maximum respect