In designing my AC wiring, I’m realizing if you have a length of 4ft from a 6500ex to a panel, you could use #10 for that length up to 70amps. If 8ft, then like #8 AWG. I was wondering why the need for #4-#6 as per the manual for short spans with these inverters? Is there something I’m missing?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Why are we overspending on AC AWG?

- Thread starter jfharper

- Start date

DIYrich

Solar Wizard

Don't want to burn your house down. Cheap insurance.

Also less power loss.

Also less power loss.

BentleyJ

Solar Wizard

YES, you are missing that #10 is WAY too small to meet code and if there were any kind of fire, even if it had nothing to do with that particular run of wire, your insurance company would surely decline coverage if they became aware. Also would not pass any kind of home inspection for a sale.

Where did you get the idea #10 is good for 70A? You've been reading too many Chinese specification sheets.

Where did you get the idea #10 is good for 70A? You've been reading too many Chinese specification sheets.

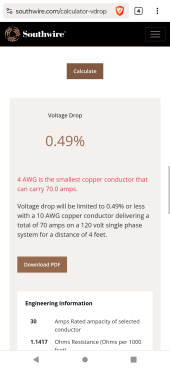

Funny. Wire gauge ampacity distance charts.Where did you get the idea #10 is good for 70A? You've been reading too many Chinese specification sheets.

So their saying yes #10, then red no….I’m confused.

They are saying yes, if all you are looking at is voltage drop, but no, if you look at the totality of everything, like code.So their saying yes #10, then red no….I’m confused.

Balrog006

Solar Enthusiast

What chart says that?Funny. Wire gauge ampacity distance charts.

As you can see posted above by 1201, #4 AWG is the minimum.

Gadwall*Drake

New Member

If you think copper is expensive, try having an electrical fire.

Ok I think I get it now, my mind is swirling with all this design information. Like you can use #10 for ground for 60 amps, that got me thinking what about lowering the conductors for various distances, etc. I think was looking at awg distance charts for other voltages than 120/240 or for DC. Got confused…better to ask and figure it out beforehand…thanks for the straightening out.They are saying yes, if all you are looking at is voltage drop, but no, if you look at the totality of everything, like code.

OffGridForGood

Catch, make or grow everything you can.

And: Only 4-feet, so no matter the cost per foot, will not cost much.

70 Amps x 240 = 16.8kW ? does this make sense with your inverter output?

The very next question: will 4AWG fit into the inverter terminals...

70 Amps x 240 = 16.8kW ? does this make sense with your inverter output?

The very next question: will 4AWG fit into the inverter terminals...

It’s one thing to use the minimum for a circuit that supplies devices for brief periods on an intermittent basis. But your inverter-to-panel wiring will have a continuous, high-current load. That’s where you want to oversize as much as you can. Less power loss, less heat, and less risk.

hwy17

Anti-Solar Enthusiast

You can't just use any ampacity chart. Chassis wiring ratings give a lot more leeway than building wiring. The NEC already gives you a break on deratings and conduit sizing for short connections.

OffGridForGood

Catch, make or grow everything you can.

Tyipcally the steady loads are small, a 50kWh per day system 'could be' 2kW continuous, and a few bigger short duration loads like well pump etc.But your inverter-to-panel wiring will have a continuous, high-current load. That’s where you want to oversize as much as you can. Less power loss, less heat, and less risk.

However, we need to size for the max current possible, and the usually very short run length makes this a good place to go as large as will fit, to cut losses for not much cost difference. I used the max that fit the inverter terminals.

The AC side of this DIY solar is really the challenging part. Modeling the solar, inverters and batt bank is sort of the same with everyone, but the ac part is tricky.You can't just use any ampacity chart. Chassis wiring ratings give a lot more leeway than building wiring. The NEC already gives you a break on deratings and conduit sizing for short connections.

hwy17

Anti-Solar Enthusiast

It is certainly a lot easier if you come to it with a building wiring understanding first. But then it feels like there's no rules on the DC side! Does NEC even have ampacity tables for battery wiring? I never thought to check.The AC side of this DIY solar is really the challenging part. Modeling the solar, inverters and batt bank is sort of the same with everyone, but the ac part is tricky.

Also, if you look at your AC wires you will see a temperature - that is what the insulation is rated for. Bare wire can handle more amps because it can radiate the heat. But when you put it in insulation you also insulated the heat. Now you need to generate less heat. Best practice- follow building codes.

#14awg - 15amps

#12 awg - 20 amps

#10awg - 30amps

#8 awg - 40amps

#6 awg - 50amps

#4awg - I don’t remember above this…

#14awg - 15amps

#12 awg - 20 amps

#10awg - 30amps

#8 awg - 40amps

#6 awg - 50amps

#4awg - I don’t remember above this…

OffGridForGood

Catch, make or grow everything you can.

Rule of thumb for short runs, and easy to remember.Also, if you look at your AC wires you will see a temperature - that is what the insulation is rated for. Bare wire can handle more amps because it can radiate the heat. But when you put it in insulation you also insulated the heat. Now you need to generate less heat. Best practice- follow building codes.

#14awg - 15amps

#12 awg - 20 amps

#10awg - 30amps

#8 awg - 40amps

#6 awg - 50amps

#4awg - I don’t remember above this…

The online calculators are a quick and easy way to check and confirm for any situation, lenght, voltage etc.

As an example of how misleading the rule of thumb can be, plug into the calculator: 120 volt, 20 amp 500 feet and see it spit out 1AWG not #12.

Hedges

I See Electromagnetic Fields!

- Joined

- Mar 28, 2020

- Messages

- 21,480

Tyipcally the steady loads are small, a 50kWh per day system 'could be' 2kW continuous, and a few bigger short duration loads like well pump etc.

However, we need to size for the max current possible, and the usually very short run length makes this a good place to go as large as will fit, to cut losses for not much cost difference. I used the max that fit the inverter terminals.

With my 405Ah 20 kWh AGM bank, 70% DoD, and Peukert, I figure 24kW from my inverters isn't continuous load. About 20 minutes. So my 4/0 jumpers between batteries are good enough. Would double up if I had 1200Ah batteries with dual terminals.

Feed-through from grid is 56A per inverter, and now that I have 60A magnetic-hydraulic breakers not 70A thermal-magnetic, 6 AWG is all good and legal.

What I missed earlier is that it's not the 90C ampacity, rather 75C due to terminal specs. But I would argue connection to terminals isn't 3 current carrying conductors in a cable, it is individual wires. Does inside a hot box full of breakers or electronics count as free air? Do we need to determine interior temperature for derating?

MichaelK

Solar Wizard

Here is one more thing to think about. The ampicity ratings for wire are based on brand-new, uncorroded wire with no broken strands. With age, bending, and poorly made connections, wire can deteriorate, and have less capacity. It's always a good plan on bumping down one gauge for an extra safety margin, and also with the idea of future equipment upgrades. Really a pain to have pull out wiring if you decide to add additional solar a year or two down the road.

OffGridForGood

Catch, make or grow everything you can.

Does ths hot box have temperature control - cooling fans?Does inside a hot box full of breakers or electronics count as free air? Do we need to determine interior temperature for derating?

Does the inverter have temperature monitoring and shut down if temperature exceeds set point?

If you wanted to use 4AWG instead of 6, would it fit your terminals without reducing ferrules?

Similar threads

- Replies

- 117

- Views

- 4K

- Replies

- 6

- Views

- 358

- Replies

- 4

- Views

- 267

- Replies

- 7

- Views

- 423