Hedges

I See Electromagnetic Fields!

- Joined

- Mar 28, 2020

- Messages

- 21,483

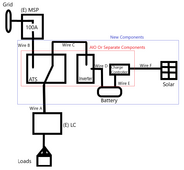

Appears you have separate 100A main breaker.

I just replaced a similar "Federal" breaker panel; in my case a 100A backfed breaker was the main.

Some people consider that brand a fire hazard, and associate it with Zinsco (different style bus), but no apparent issues with mine.

diysolarforum.com

diysolarforum.com

If the breaker panel busbar is 100A, you can install a 20A PV breaker at far end according to 120% rule (which assumes backfeed). That's good for 16A continuous.

Is the wire between your 100A main breaker and the meter accessible?

I'd consider having utility yank the meter while installing a line-side tap going to maybe 100A or 60A transfer switch. That would feed meter.

But it would have ability to draw its current in addition to your 100A main breaker and panel.

Alternatively, I'd consider installing a 100A backfed main breaker in the panel.

Meter --> 100A main --> 100A backfed main.

Then I'd do a load-side tap between the two 100A breakers to feed 100A fused disconnect for inverter.

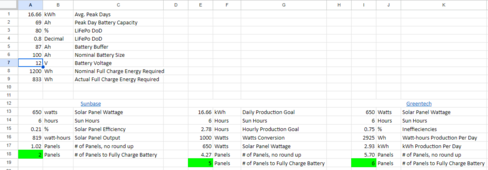

35kW/day you say? If in summer, about 7kW (STC) of panels would cover that.

Half as much if most days are half and you can switch to grid for those.

How much of the 35kW or 16kW is during early morning/night/evening? That's how much battery you want as a minimum.

With about 6kW peak charging at 12V, that's 500A.

I think you're squarely in 48V system territory.

7kW of PV, 6kW of inverter, mounting hardware and wires, should be doable around $3000 to $8000.

28kWh of LiFePO4 (2x PowerPro) about $8000.

I just replaced a similar "Federal" breaker panel; in my case a 100A backfed breaker was the main.

Some people consider that brand a fire hazard, and associate it with Zinsco (different style bus), but no apparent issues with mine.

Cost for utility transformer installation?

slightly OT. There was a review of the Emporia Energy Monitor on Amazon, which mentioned that the house meter records more kwh usage when the pull is unbalanced between L1/L2. Is this a possibility ?

If the breaker panel busbar is 100A, you can install a 20A PV breaker at far end according to 120% rule (which assumes backfeed). That's good for 16A continuous.

Is the wire between your 100A main breaker and the meter accessible?

I'd consider having utility yank the meter while installing a line-side tap going to maybe 100A or 60A transfer switch. That would feed meter.

But it would have ability to draw its current in addition to your 100A main breaker and panel.

Alternatively, I'd consider installing a 100A backfed main breaker in the panel.

Meter --> 100A main --> 100A backfed main.

Then I'd do a load-side tap between the two 100A breakers to feed 100A fused disconnect for inverter.

35kW/day you say? If in summer, about 7kW (STC) of panels would cover that.

Half as much if most days are half and you can switch to grid for those.

How much of the 35kW or 16kW is during early morning/night/evening? That's how much battery you want as a minimum.

With about 6kW peak charging at 12V, that's 500A.

I think you're squarely in 48V system territory.

7kW of PV, 6kW of inverter, mounting hardware and wires, should be doable around $3000 to $8000.

28kWh of LiFePO4 (2x PowerPro) about $8000.